Theodoros Benai

Mechanical

- Jun 1, 2025

- 1

Hi all,

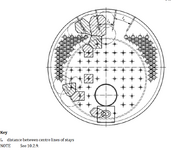

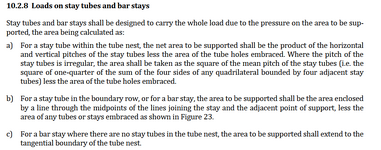

I'm a mechanical engineer working in the boiler industry and currently dealing with EN 12953, specifically Clause 10.2.8: Loads on stay tubes and bar stays. According to the standard, the end plate is split into sub-areas, each assigned to a stay tube or bar stay. This distribution is used to calculate the pressure load each support element carries and eventually determine the required thickness of the end plate.

However, I'm having trouble understanding how exactly the standard defines and separates these pressure-loaded areas. Despite reading the explanation and reviewing Figure 23 from the standard, I haven’t been able to replicate the area divisions.

How are the boundaries between adjacent supports (especially at the edges or near irregular arrangements) determined?

I’ve attached the relevant excerpt and figure from the standard for reference.

Any help—be it a clearer explanation, a worked example, or a rule-of-thumb approach—would be greatly appreciated!

Thanks in advance!

I'm a mechanical engineer working in the boiler industry and currently dealing with EN 12953, specifically Clause 10.2.8: Loads on stay tubes and bar stays. According to the standard, the end plate is split into sub-areas, each assigned to a stay tube or bar stay. This distribution is used to calculate the pressure load each support element carries and eventually determine the required thickness of the end plate.

However, I'm having trouble understanding how exactly the standard defines and separates these pressure-loaded areas. Despite reading the explanation and reviewing Figure 23 from the standard, I haven’t been able to replicate the area divisions.

How are the boundaries between adjacent supports (especially at the edges or near irregular arrangements) determined?

I’ve attached the relevant excerpt and figure from the standard for reference.

Any help—be it a clearer explanation, a worked example, or a rule-of-thumb approach—would be greatly appreciated!

Thanks in advance!