Good day,

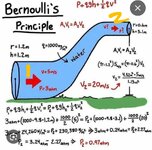

Gauge pressure measures static pressure component of Bernoulli equation. Say l put gauge pressure between point 1 and 2, assuming minor head loss due pipe length, the 2 gauges will read differently due to potential energy difference and also due pipe diameter. See attached. l am asking a booster system requires 8bar of steam. lf l supply it with 8 bar of steam in 3/4inch pipe vs l supply it with 8 bar steam 1/2 inch pipe, l assume mass flowrate will be totally different

Gauge pressure measures static pressure component of Bernoulli equation. Say l put gauge pressure between point 1 and 2, assuming minor head loss due pipe length, the 2 gauges will read differently due to potential energy difference and also due pipe diameter. See attached. l am asking a booster system requires 8bar of steam. lf l supply it with 8 bar of steam in 3/4inch pipe vs l supply it with 8 bar steam 1/2 inch pipe, l assume mass flowrate will be totally different