jamiethekiller

Mechanical

- May 2, 2025

- 20

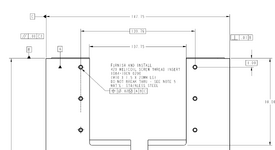

I have a big weldment. All sides are to be machined and held flat ~.01"(still working that out). From one long end to the other i was going to hold that dimension as a datum and then hold the rectangular hole pattern to that dimension. Doing it this way i can keep the hole pattern 'symmetric' to the overall width dimension(+/- .01") instead of whats historically been done(which is datum on one side and then dimensioning from that datum.

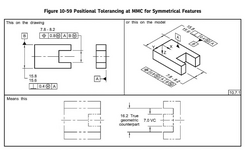

My problem comes in then, how do i communicate that i want the sides flat and parallel to each other and perpendicular to the top surface as well? At first i thought i would use Flatness on the width FoS but that doesn't seem to commincate that. Can i have my overall width dimension be a datum([-C-]) and THEN have one of those surfaces of that FoS width be a datum as well to communicate flatness and parallelism? Figure 10-59(2018) intrigued me but i couldnt' find anything about the perpendicular callout on the FoS in the standard. Its near the same shape(dimensions wildly different) but the bolt pattern follows the slot.

I can go back to the tried and true way and just dimension from one surface and 'live' with the bolt pattern potentially not being 100% symmetric(its not that big of a deal) but i've also come across this same kinda exercise on other parts so looking for clarity.

tldr:

need help identifying Datums so that my bolt pattern is symmetric to the overall width of the part but each side of the width needs to be flat/parallel to each other and then perpendicular to another top surface.

Thanks

My problem comes in then, how do i communicate that i want the sides flat and parallel to each other and perpendicular to the top surface as well? At first i thought i would use Flatness on the width FoS but that doesn't seem to commincate that. Can i have my overall width dimension be a datum([-C-]) and THEN have one of those surfaces of that FoS width be a datum as well to communicate flatness and parallelism? Figure 10-59(2018) intrigued me but i couldnt' find anything about the perpendicular callout on the FoS in the standard. Its near the same shape(dimensions wildly different) but the bolt pattern follows the slot.

I can go back to the tried and true way and just dimension from one surface and 'live' with the bolt pattern potentially not being 100% symmetric(its not that big of a deal) but i've also come across this same kinda exercise on other parts so looking for clarity.

tldr:

need help identifying Datums so that my bolt pattern is symmetric to the overall width of the part but each side of the width needs to be flat/parallel to each other and then perpendicular to another top surface.

Thanks