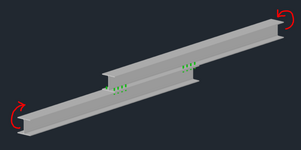

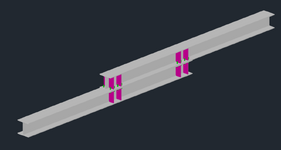

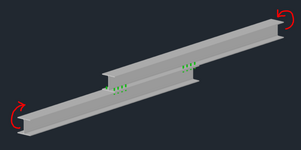

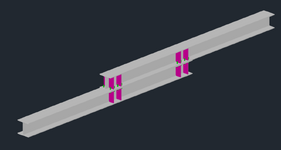

I have a situation where there will be two steel beams bolted flange-to-flange and subject mainly to in-plane bending, the intention is to create a full moment splice.

Does this kind of steel connection have a name? And are there any design guides or papers that discuss it?

Are there any peculiarities for this kind of connection I would need to consider?

Designing the connection to achieve section capacity is straightforward enough. But what about LTB considerations? Would this need web stiffeners to maintain torsional stiffness through the connection similar to below? I appreciate this probably heavily depends on the loading and support arrangement, but general advice would be great.

Appreciate any insights, thanks all

Does this kind of steel connection have a name? And are there any design guides or papers that discuss it?

Are there any peculiarities for this kind of connection I would need to consider?

Designing the connection to achieve section capacity is straightforward enough. But what about LTB considerations? Would this need web stiffeners to maintain torsional stiffness through the connection similar to below? I appreciate this probably heavily depends on the loading and support arrangement, but general advice would be great.

Appreciate any insights, thanks all