BenStewart

Mechanical

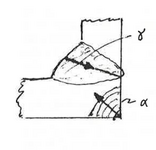

My understanding, from the test data summarised by Rodabaugh in WRC 335 (page 24-25) was that a radius at the inside corner (crotch) of a nozzle does not significant effect the fatigue performance of a nozzle connection under cyclic pressure loading. A comparison of fatigue tests of identical designs is made with a square edge and 1/8" radius is made. Another of his reports, I accessed from the OSTI website, stated similar. I've attached a sketch from WRC 335 - location alpha is what I'm discussing.

I am evaluating several vertical Pressure Swing Adsorbers (VIII-2 designs, cycles every ~5 min at ~80% MAWP ~ambient temperature) for life extension. The focus is naturally on the long. seam weld (peaking, OOR, misalignment) but I am reviewing all locations including attachments - nozzles, skirt, etc. The fabricator included a generous radius at the nozzle inside corner, ~3/4", which seems to contradict the WRC 335 conclusion. The European Gas Association document also doesn't mention anything about this location wrt fatigue.

My questions is what are your experiences with fatigue at this location and is a large radius warranted/typical in high cyclic pressure services? To me, a radius intuitively makes sense here, but going to such a large radius (unless balanced with a radius on the outside) would arguably increase the stress at this location as more material is removed. I will be analysing a few axisymmetric models to better understand, but I would really appreciate your insights.

Thanks,

Ben

I am evaluating several vertical Pressure Swing Adsorbers (VIII-2 designs, cycles every ~5 min at ~80% MAWP ~ambient temperature) for life extension. The focus is naturally on the long. seam weld (peaking, OOR, misalignment) but I am reviewing all locations including attachments - nozzles, skirt, etc. The fabricator included a generous radius at the nozzle inside corner, ~3/4", which seems to contradict the WRC 335 conclusion. The European Gas Association document also doesn't mention anything about this location wrt fatigue.

My questions is what are your experiences with fatigue at this location and is a large radius warranted/typical in high cyclic pressure services? To me, a radius intuitively makes sense here, but going to such a large radius (unless balanced with a radius on the outside) would arguably increase the stress at this location as more material is removed. I will be analysing a few axisymmetric models to better understand, but I would really appreciate your insights.

Thanks,

Ben