Hi all, I think I have a relatively simple question that we are getting pushback on.

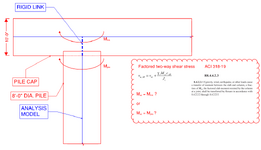

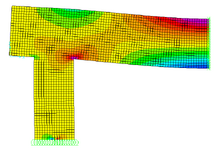

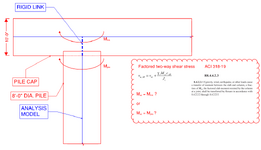

Please see the attached sketch. We have a very thick pile cap and a very large pile.

For the two-way shear stress check, would you take Msc as Mpile (moment at bottom face of pile cap), or would you take Msc as Mlink (moment at centerline of pile cap)?

I think the answer would simply be the centerline if the pile cap was thin. However, given that it's an extremely thick and stiff pile cap, we are getting pushback on whether the moment we consider should actually be at the bottom face of the pile cap.

Any thoughts or references are very welcome. Thanks in advance!

Please see the attached sketch. We have a very thick pile cap and a very large pile.

For the two-way shear stress check, would you take Msc as Mpile (moment at bottom face of pile cap), or would you take Msc as Mlink (moment at centerline of pile cap)?

I think the answer would simply be the centerline if the pile cap was thin. However, given that it's an extremely thick and stiff pile cap, we are getting pushback on whether the moment we consider should actually be at the bottom face of the pile cap.

Any thoughts or references are very welcome. Thanks in advance!