leon_har_dt

Mechanical

Dear All,

i hope you are doing Ok,

one constructive and code question.

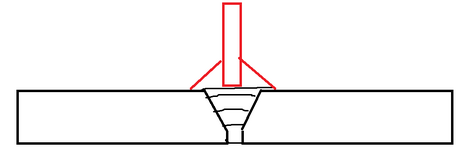

Can be a stiffner ring be attached by welding above a groove shell joint? (as mention in the image)

I read UG-30, and it doesn't mention or doesn't restrict to do it

Why to do it? I'm validating a design of a HX with a reducer cone. for 1-8 the ring has to be situated within a calculated distance.

I'll appreciate any answer

Thanks!

L.

i hope you are doing Ok,

one constructive and code question.

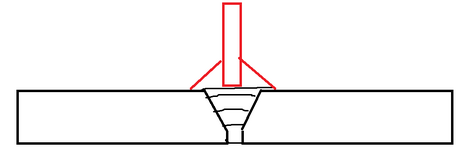

Can be a stiffner ring be attached by welding above a groove shell joint? (as mention in the image)

I read UG-30, and it doesn't mention or doesn't restrict to do it

Why to do it? I'm validating a design of a HX with a reducer cone. for 1-8 the ring has to be situated within a calculated distance.

I'll appreciate any answer

Thanks!

L.