I am having a difficult determining in NX the edge blend errors. In I-deas the there are three different type of colors to notify you, the type of fillet error you had in the model. For example a yellow node in I-deas would mean, most of the time, that there is was an edge that was filleted and now that edge no longer exist. (missing edge). Or a red node means the fillet just died and or failed.

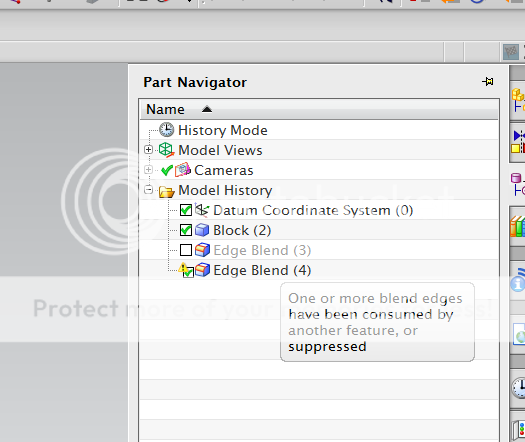

In Nx I get many many Yellow Exclamation points which could mean anything from a missing edge to just a small change to the path of the fillet. I also get the red X which I know that the fillet failed.

My question is about the yellow Exclamtion points. My part history is full of these. I am working on a die casting that is fully filleted. Any little change these Yellow exclamtion points light up my history tree.

What is the best way to manage these? My workflow is that I go into the fillet step, examine where the fillet is, then make sure all is ok, after that I hit the X by the dimension and update. Most of the time the fillet works and the change is small due to model changes.

Thanks for any feedback.

In Nx I get many many Yellow Exclamation points which could mean anything from a missing edge to just a small change to the path of the fillet. I also get the red X which I know that the fillet failed.

My question is about the yellow Exclamtion points. My part history is full of these. I am working on a die casting that is fully filleted. Any little change these Yellow exclamtion points light up my history tree.

What is the best way to manage these? My workflow is that I go into the fillet step, examine where the fillet is, then make sure all is ok, after that I hit the X by the dimension and update. Most of the time the fillet works and the change is small due to model changes.

Thanks for any feedback.