Hello.

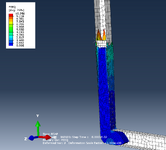

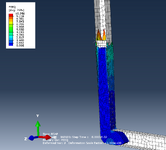

I have a problem with modelling of ECAP (Equal Channel Angular Pressing) process. The problem is, that the mesh distorts heavily – it looks like the material (billet) flows between the punch and the die during the processing:

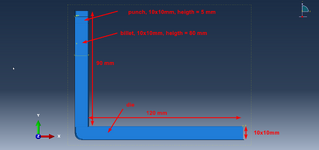

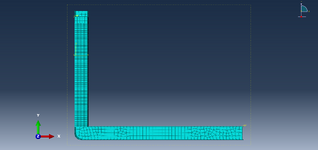

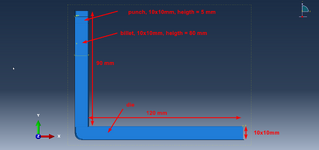

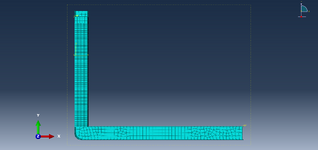

The assembly is given below:

The ECAP canal has 10 x 10 mm rectangular dimensions.

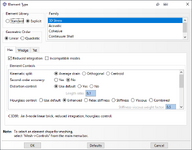

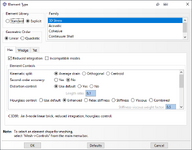

I am using:

Young's modulus is 44700.

Poisson's ratio is 0.35.

Density equals 1.75e-9.

I am attaching also .inp file.

What am I doing wrong?

I have a problem with modelling of ECAP (Equal Channel Angular Pressing) process. The problem is, that the mesh distorts heavily – it looks like the material (billet) flows between the punch and the die during the processing:

The assembly is given below:

The ECAP canal has 10 x 10 mm rectangular dimensions.

I am using:

- Punch and die are discrete rigid parts

- Abaqus Explicit with 0.2 s time step.

- Z symmetry

- 0.1 friction coefficient (but tried also higher)

- I tried general contact and surface-to-surface contact

- I made tie between the punch and billet – this helped a little – nodes on the top surface of the billet didn’t move relative to the billet, but billet’s nodes below them moved

Young's modulus is 44700.

Poisson's ratio is 0.35.

Density equals 1.75e-9.

I am attaching also .inp file.

What am I doing wrong?