hello guys, im recently study the non-uniform temperature distribution and deformation in aero-engines(turbojet turbofan turboshaft), and the un-uniform deformation is a typical problem remains unsloved, but I cant find any material to learn from(for example, OTDF is a factor to define the temperature distribution of the combustion chamber outlet) . so is anybody knows how to deal with this kind of problems? maybe we can discuss it?

. so is anybody knows how to deal with this kind of problems? maybe we can discuss it?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discussion on circumferential non-uniform temperature distribution and deformation in aero-engines

- Thread starter Chaos2Max

- Start date

SWComposites

Aerospace

i suspect this info is proprietary to the engine manufacturers

Maybe some useful info in AIAA or SAE or documents/reports/standards...

SAE AIRxxx, ARPxxx, ARPxx, text books, published papers, etc. Example...

SAE AS681 Gas Turbine Engine Performance Presentation for Computer Programs

SAE AIR1419 Inlet Total-Pressure Distortion Considerations for Gas-Turbine Engines

AIAA has thousands of papers, every topic.

Bla bla bla...

SAE AIRxxx, ARPxxx, ARPxx, text books, published papers, etc. Example...

SAE AS681 Gas Turbine Engine Performance Presentation for Computer Programs

SAE AIR1419 Inlet Total-Pressure Distortion Considerations for Gas-Turbine Engines

AIAA has thousands of papers, every topic.

Bla bla bla...

- Thread starter

- #4

Thx~ but its also a problem related to manufacturers, but the contribution is not so significant. you know for turbine casing, due to the circumferential non-uniform temperature distribution(high temp gas and maybe ACC) the deformation is the non-uniform. which will lead to non-uniform tip clearance, you cant just evaluate the performance of your engine with a single 1D valve of Tip Clearance. you need 3D INFO~i suspect this info is proprietary to the engine manufacturers

- Thread starter

- #5

YES Taylor. i've search those website, not much useful information.Maybe some useful info in AIAA or SAE or documents/reports/standards...

SAE AIRxxx, ARPxxx, ARPxx, text books, published papers, etc. Example...

SAE AS681 Gas Turbine Engine Performance Presentation for Computer Programs

SAE AIR1419 Inlet Total-Pressure Distortion Considerations for Gas-Turbine Engines

AIAA has thousands of papers, every topic.

Bla bla bla...

Have you answered your own question ?

I'd've thought that engines were very susceptible to even small loads, but if this is a thing that OEMs don't worry about, then why you ?

I'd've thought (like SWC) that OEMs did worry about this, and do so in a proprietary manner, so you may not find open sources on this.

I'd've thought that OEMs worried extensively about thermal effects (the the impact of these effects on the small clearances inside the engine.

Now maybe the combustion chambers massively overrule other thermal effects (like temperature rise due to compression).

Maybe you can explain your problem some more ... "the non-uniform temperature distribution and deformation in aero-engines". Are you looking at the engine shaft specifically ? A multi-shaft engine ??.

In my ignorance I'd expect that the combustion chambers are the biggest heat source, and the engine gradually heat soaks as it runs for several hours.

But outside air is at something like -30degC, so there's a bunch of thermal modelling going on.

So by "non-uniform temperature", do you mean some of the shaft is feeling the combustion chamber temp and some other parts are feeling the outside air ?

I'd've thought that engines were very susceptible to even small loads, but if this is a thing that OEMs don't worry about, then why you ?

I'd've thought (like SWC) that OEMs did worry about this, and do so in a proprietary manner, so you may not find open sources on this.

I'd've thought that OEMs worried extensively about thermal effects (the the impact of these effects on the small clearances inside the engine.

Now maybe the combustion chambers massively overrule other thermal effects (like temperature rise due to compression).

Maybe you can explain your problem some more ... "the non-uniform temperature distribution and deformation in aero-engines". Are you looking at the engine shaft specifically ? A multi-shaft engine ??.

In my ignorance I'd expect that the combustion chambers are the biggest heat source, and the engine gradually heat soaks as it runs for several hours.

But outside air is at something like -30degC, so there's a bunch of thermal modelling going on.

So by "non-uniform temperature", do you mean some of the shaft is feeling the combustion chamber temp and some other parts are feeling the outside air ?

what you are asking for is strictly controlled, properietary information, part of specific DPs, directly related to engine performance - you will have no access to this untill you will be a member of inner circle of trust at GE, PW, RR or Safran.... not just emplyee, but you have to work for a team which has access to this type of information on "need to know" basis

Last edited:

SWComposites

Aerospace

So Chaos, are you a student? Or do you work for an engine company? Or what motivates your interest in this topic?

hello guys, im recently study the non-uniform temperature distribution and deformation in aero-engines(turbojet turbofan turboshaft), and the un-uniform deformation is a typical problem remains unsloved, but I cant find any material to learn from(for example, OTDF is a factor to define the temperature distribution of the combustion chamber outlet). so is anybody knows how to deal with this kind of problems? maybe we can discuss it?

Circumferential Non-Uniformity in Temperature Distribution and Resulting Deformation in Jet Engines

1. Circumferential Non-Uniformity in Temperature Distribution

In jet engines — especially in the turbine section — the temperature field is ideally expected to be uniform circumferentially around the engine centerline. However, in practice, due to various reasons like:

- Non-uniform combustion (hot streaks from burners)

- Secondary airflows (cooling air leaks, purge flows)

- Disturbances from upstream components (like distorted flow from compressors)

- Manufacturing tolerances and operational wear

the temperature field varies as you move around the circumference at a fixed axial location.

This non-uniformity is often called:

- Hot streaks (regions of locally higher temperature)

- Cold sectors (regions of locally lower temperature)

Typically, these circumferential differences can be on the order of tens to hundreds of degrees Kelvin, depending on operating conditions.

2. Mechanisms Leading to Temperature Non-Uniformity

- Combustor Pattern Factors: In annular combustors, even if designed symmetrically, imperfect fuel-air mixing leads to discrete "hot spots."

- Cooling Flows: Turbine blades and vanes are film-cooled. The coolant might not be perfectly uniform, causing local cold regions.

- Burner Misalignment or Malfunction: Faulty nozzles or injectors create localized rich or lean zones.

- Thermal Boundary Layers: Differences in the cooling efficiency along casing or hub walls can create temperature gradients.

3. Resulting Deformation Phenomena

Now, non-uniform temperatures cause non-uniform thermal expansion in engine components.

Key phenomena include:

3.1 Thermally Induced Ovalization ("Thermal Bowing")

- Turbine casings, disks, and rotors, which are typically circular, can deform into an oval shape due to uneven expansion.

- Hot sectors expand more → pushing the casing outward locally.

- Cold sectors expand less → staying closer to original dimensions.

This ovalization leads to variations in tip clearances between blades and casing around the circumference, impacting efficiency and potentially causing rubs (physical contact).

3.2 Rotor Disk "Tilt" and "Wobble"

- Non-uniform heating across the disk face can create disk coning or wobble, where the rotor hub gets displaced axially and radially.

- This introduces unwanted vibrations and can accelerate fatigue damage.

3.3 Creep and Material Fatigue

- Areas under higher temperatures creep more (plastic deformation over time), leading to out-of-roundness even when the engine cools down.

- Fatigue cycles are exacerbated where temperature gradients cause large thermomechanical stresses.

3.4 Thermomechanical Stress

Thermal non-uniformities cause localized stresses because different parts of the component try to expand differently, but are mechanically connected:

- In extreme cases, this stress can cause cracks, especially at cooling holes or blade roots.

- In disks, it can also drive Low Cycle Fatigue (LCF) or Thermal Mechanical Fatigue (TMF) failure modes.

4. Engineering Mitigation Strategies

To control circumferential temperature non-uniformity and deformation effects, engineers design:

- Advanced combustors with better fuel-air mixing (e.g., lean-premixed, pre-vaporized combustors).

- Careful cooling flow management: optimizing the distribution and flow rates of coolant air.

- Flexible components: casings and mounts that can accommodate thermal growth.

- Tip clearance control systems: using active clearance control with cooling air to shrink or expand the casing dynamically.

- Thermal barrier coatings (TBCs) to equalize surface temperatures.

to realize how sensitive this information is i just point you to the fact that only one of listed by me companies is using ACC (active clearace control) system in their engines and this company is finding this system as a factor giving them significant edge over competition

mfgenggear

Aerospace

I will throw my two cents in here.

Being naive the engine has a start up

Up procedure for the engine.

The issue is there thick and thin sections.

The thin section heat up faster. Than the thin sections causing un uninformed thermal expansion. So must mitigate distortion,

Which causes emence stress.

Which causes to propagate cracks.

Due to balancing issues, close tolerance on the rotating shafts, bearings. I been researching maintenance issues.

Making sure the rotating assemblies do and must not exceed thermal temperatures.

Monitoring Temps at these assemblies.

As every one has posted, these are built into

The design. As long as the thermal properties are maintained. Air flow, lubrication and what not.

I had the honor to be part of the projects

With hot sections that utilize high temperture

Exotic alloys , inconel 718, inconel 625, waspalloy,

Being naive the engine has a start up

Up procedure for the engine.

The issue is there thick and thin sections.

The thin section heat up faster. Than the thin sections causing un uninformed thermal expansion. So must mitigate distortion,

Which causes emence stress.

Which causes to propagate cracks.

Due to balancing issues, close tolerance on the rotating shafts, bearings. I been researching maintenance issues.

Making sure the rotating assemblies do and must not exceed thermal temperatures.

Monitoring Temps at these assemblies.

As every one has posted, these are built into

The design. As long as the thermal properties are maintained. Air flow, lubrication and what not.

I had the honor to be part of the projects

With hot sections that utilize high temperture

Exotic alloys , inconel 718, inconel 625, waspalloy,

- Thread starter

- #12

Thank u RB1957. im now mainly foucs on turbine casing deformation.Have you answered your own question ?

I'd've thought that engines were very susceptible to even small loads, but if this is a thing that OEMs don't worry about, then why you ?

I'd've thought (like SWC) that OEMs did worry about this, and do so in a proprietary manner, so you may not find open sources on this.

I'd've thought that OEMs worried extensively about thermal effects (the the impact of these effects on the small clearances inside the engine.

Now maybe the combustion chambers massively overrule other thermal effects (like temperature rise due to compression).

Maybe you can explain your problem some more ... "the non-uniform temperature distribution and deformation in aero-engines". Are you looking at the engine shaft specifically ? A multi-shaft engine ??.

In my ignorance I'd expect that the combustion chambers are the biggest heat source, and the engine gradually heat soaks as it runs for several hours.

But outside air is at something like -30degC, so there's a bunch of thermal modelling going on.

So by "non-uniform temperature", do you mean some of the shaft is feeling the combustion chamber temp and some other parts are feeling the outside air ?

Because the shaft of an aero-engine counteracts all kinds of non-uniform deformations due to centrifugal force during rotation, its non-uniform deformations are basically not considered.

as for turbine casing. I want to know the main reason,I would like to know the main factors that lead to its non-uniform deformation, and hopefully, Build a model that describes it(how to add up the boundary condition during CFD or FEM)

now i know a few fators(ACC, three-dimensional construction--load-bearing casing of turbine, non-uniform temp of gas, axial force of main flow,etc)

after this, maybe i will start design the structure of turbine casing making it stay uniform during the whole engine working process.

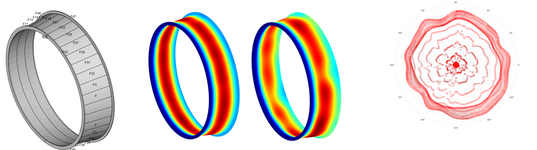

and the pic shows the non-uniform deformation of a simple turbine casing under cruise state.

Attachments

- Thread starter

- #13

because im study on the problem right now. which bothering me for a long time ,l want to slove it. if we dont consider the non-uniform at design stage. the non-uniform deformation will causing abrasion of blade and casing during ground test of an engine.what you are asking for is strictly controlled, properietary information, part of specific DPs, directly related to engine performance - you will have no access to this untill you will be a member of inner circle of trust at GE, PW, RR or Safran.... not just emplyee, but you have to work for a team which has access to this type of information on "need to know" basis

- Thread starter

- #14

yes SWC. IM a student. I want to make this problem my subject.So Chaos, are you a student? Or do you work for an engine company? Or what motivates your interest in this topic?

- Thread starter

- #15

THANKS U FOR THIS INFOMATION. great help, but it looks like answer for AI.Circumferential Non-Uniformity in Temperature Distribution and Resulting Deformation in Jet Engines

1. Circumferential Non-Uniformity in Temperature Distribution

In jet engines — especially in the turbine section — the temperature field is ideally expected to be uniform circumferentially around the engine centerline. However, in practice, due to various reasons like:

- Non-uniform combustion (hot streaks from burners)

- Secondary airflows (cooling air leaks, purge flows)

- Disturbances from upstream components (like distorted flow from compressors)

- Manufacturing tolerances and operational wear

the temperature field varies as you move around the circumference at a fixed axial location.

This non-uniformity is often called:

- Hot streaks (regions of locally higher temperature)

- Cold sectors (regions of locally lower temperature)

Typically, these circumferential differences can be on the order of tens to hundreds of degrees Kelvin, depending on operating conditions.

2. Mechanisms Leading to Temperature Non-Uniformity

- Combustor Pattern Factors: In annular combustors, even if designed symmetrically, imperfect fuel-air mixing leads to discrete "hot spots."

- Cooling Flows: Turbine blades and vanes are film-cooled. The coolant might not be perfectly uniform, causing local cold regions.

- Burner Misalignment or Malfunction: Faulty nozzles or injectors create localized rich or lean zones.

- Thermal Boundary Layers: Differences in the cooling efficiency along casing or hub walls can create temperature gradients.

3. Resulting Deformation Phenomena

Now, non-uniform temperatures cause non-uniform thermal expansion in engine components.

Key phenomena include:

3.1 Thermally Induced Ovalization ("Thermal Bowing")

- Turbine casings, disks, and rotors, which are typically circular, can deform into an oval shape due to uneven expansion.

- Hot sectors expand more → pushing the casing outward locally.

- Cold sectors expand less → staying closer to original dimensions.

This ovalization leads to variations in tip clearances between blades and casing around the circumference, impacting efficiency and potentially causing rubs (physical contact).

3.2 Rotor Disk "Tilt" and "Wobble"

- Non-uniform heating across the disk face can create disk coning or wobble, where the rotor hub gets displaced axially and radially.

- This introduces unwanted vibrations and can accelerate fatigue damage.

3.3 Creep and Material Fatigue

- Areas under higher temperatures creep more (plastic deformation over time), leading to out-of-roundness even when the engine cools down.

- Fatigue cycles are exacerbated where temperature gradients cause large thermomechanical stresses.

3.4 Thermomechanical Stress

Thermal non-uniformities cause localized stresses because different parts of the component try to expand differently, but are mechanically connected:

- In extreme cases, this stress can cause cracks, especially at cooling holes or blade roots.

- In disks, it can also drive Low Cycle Fatigue (LCF) or Thermal Mechanical Fatigue (TMF) failure modes.

4. Engineering Mitigation Strategies

To control circumferential temperature non-uniformity and deformation effects, engineers design:

- Advanced combustors with better fuel-air mixing (e.g., lean-premixed, pre-vaporized combustors).

- Careful cooling flow management: optimizing the distribution and flow rates of coolant air.

- Flexible components: casings and mounts that can accommodate thermal growth.

- Tip clearance control systems: using active clearance control with cooling air to shrink or expand the casing dynamically.

- Thermal barrier coatings (TBCs) to equalize surface temperatures.

- Thread starter

- #16

yes i guess this company is GE? because thier CFM56 series have ACC? DO U WORK FOR THEM jaceb? looks like u are an expert, can u give me more infomation plsto realize how sensitive this information is i just point you to the fact that only one of listed by me companies is using ACC (active clearace control) system in their engines and this company is finding this system as a factor giving them significant edge over competition

- Thread starter

- #17

yes Your analysis is correct. thank u mfgenggear, what if i dont use alloys in those part?? like Composites(CMC SWC,ETC) HAVE U considered it?I will throw my two cents in here.

Being naive the engine has a start up

Up procedure for the engine.

The issue is there thick and thin sections.

The thin section heat up faster. Than the thin sections causing un uninformed thermal expansion. So must mitigate distortion,

Which causes emence stress.

Which causes to propagate cracks.

Due to balancing issues, close tolerance on the rotating shafts, bearings. I been researching maintenance issues.

Making sure the rotating assemblies do and must not exceed thermal temperatures.

Monitoring Temps at these assemblies.

As every one has posted, these are built into

The design. As long as the thermal properties are maintained. Air flow, lubrication and what not.

I had the honor to be part of the projects

With hot sections that utilize high temperture

Exotic alloys , inconel 718, inconel 625, waspalloy,

mfgenggear

Aerospace

I have no useful info, not a composites guyyes Your analysis is correct. thank u mfgenggear, what if i dont use alloys in those part?? like Composites(CMC SWC,ETC) HAVE U considered it?

THANKS U FOR THIS INFOMATION. great help, but it looks like answer for AI.

Attachments

- Thread starter

- #20

Similar threads

- Replies

- 9

- Views

- 2K

- Question

- Replies

- 13

- Views

- 14K

- Replies

- 11

- Views

- 6K

- Replies

- 26

- Views

- 1K

- Replies

- 22

- Views

- 3K