Hey folks,

Would like an idiot check.

I'm working on designing the camshaft for a small 4 stroke generator engine that will run at 5000 rpm. I've spent about 3 weeks total on cam design thus far and am having an absolute panic attack. lol

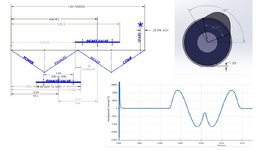

the cam has a base circle of Ø1.125 and a roller follower Ø.5

I started with cycloid, then modified trap, 3-4-5, then higher order... started messing with Cubic Bézier splines... and more less ended back up with a 3-4-5.

Anyway... I've been trying to keep things under 100g of acceleration and finally made it.

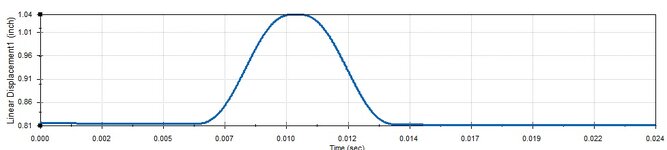

Ended up with a 3-4-5 that has a 100deg rise, and 100 deg fall no dwell. The actual equation says I should be getting about 79g but the simulation came back with a peak of 96.7g. I think that has everything to do with roller contact angle/pressure angle...

That said I was like oh... I'll just plot the roller center then cut out as it rotates to get the lifter to do what I want... omg. that's not possible... at least my simple brain can deal with it.

Anywhoo... I'm already at 200 degrees seat to seat on the cam. It's boxer engine, so no offsetting the cam bore I think this is it.

Is there anything else I can do?

Would like an idiot check.

I'm working on designing the camshaft for a small 4 stroke generator engine that will run at 5000 rpm. I've spent about 3 weeks total on cam design thus far and am having an absolute panic attack. lol

the cam has a base circle of Ø1.125 and a roller follower Ø.5

I started with cycloid, then modified trap, 3-4-5, then higher order... started messing with Cubic Bézier splines... and more less ended back up with a 3-4-5.

Anyway... I've been trying to keep things under 100g of acceleration and finally made it.

Ended up with a 3-4-5 that has a 100deg rise, and 100 deg fall no dwell. The actual equation says I should be getting about 79g but the simulation came back with a peak of 96.7g. I think that has everything to do with roller contact angle/pressure angle...

That said I was like oh... I'll just plot the roller center then cut out as it rotates to get the lifter to do what I want... omg. that's not possible... at least my simple brain can deal with it.

Anywhoo... I'm already at 200 degrees seat to seat on the cam. It's boxer engine, so no offsetting the cam bore I think this is it.

Is there anything else I can do?