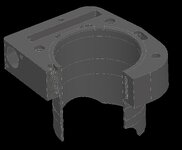

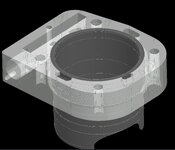

Hi there, I have been tasked with designing a big bore cylinder for a 13:1 compression ratio 450cc single-cylinder 4-stroke MX engine making ~65 bhp. I am trying to decide what reasonable static cylinder pressures I should use in Inventor stress analysis. I don't have any other FEA, CFD, or CHT software—or formal education in those areas—so my analysis is limited. From my research, something like about 2 ksi across the ID and full stroke of the cylinder is probably reasonable for verifying normal operation and fatigue life. For my extreme pre-ignition/knocking case, I’ve been applying a 6mm band (carbon band height on OEM) from the top of the cylinder/case interface on the bore at 4.5 ksi, and using 2 ksi for the rest of the wall to be extra conservative.

Even under those unrealistic conditions, my design is mostly alright—the cylinder wall stays below yield, except for some small but high stress concentrations. These happen where the case has interrupted bearing contact with the cylinder barrel at the coolant outlet ports. This is my first time doing anything motorsports-related, so I'm very open to suggestions or critiques.

Also, if you have any design rules or tricks to share on water jacket design and analysis, I’d appreciate it. I’m short on space because I’m trying to keep the cylinder compatible without modifying any of the other parts. Keeping the cylinder wall strong has already forced me to narrow the water jacket flow area, even though I’ve expanded it outward from stock. But it's not a working design if it can't flow properly. Sorry about the mixed units—the OEM part was designed in metric, but my workplace uses inches and psi, so my units are all over the place.

Even under those unrealistic conditions, my design is mostly alright—the cylinder wall stays below yield, except for some small but high stress concentrations. These happen where the case has interrupted bearing contact with the cylinder barrel at the coolant outlet ports. This is my first time doing anything motorsports-related, so I'm very open to suggestions or critiques.

Also, if you have any design rules or tricks to share on water jacket design and analysis, I’d appreciate it. I’m short on space because I’m trying to keep the cylinder compatible without modifying any of the other parts. Keeping the cylinder wall strong has already forced me to narrow the water jacket flow area, even though I’ve expanded it outward from stock. But it's not a working design if it can't flow properly. Sorry about the mixed units—the OEM part was designed in metric, but my workplace uses inches and psi, so my units are all over the place.