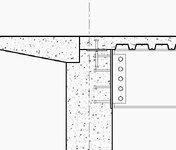

I have a commercial basement foundation wall resisting about 14' of soil load, so the reaction at the top of the wall is significant - about 4.7 kips per foot ultimate. Typically when we have this condition, our top of foundation wall goes all the way up to the finished floor level so that the top of the wall can laterally bear directly against the side of our slab-on-metal deck. That makes this condition easy to design as there is no connection required to resist this lateral soil load, and typically there is an exterior stud wall over this location so that it can't be seen. However, on my current project, the basement only occurs at about 50% of the building footprint, so we have several walls that are directly below finished spaces and the architect would prefer the top of wall to be below the slab-on-metal deck.

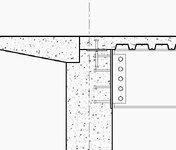

So now we have the question on how to connect the deck to the top of the wall to resist this large out-of-plane load. Headed anchors can't resist the load as the breakout is about 75% overstressed. We don't have beams framing perpendicularly into the wall at all locations so we can't use the beams either. And since we're only using a 4" total slab thickness with the metal deck, developing rebar into the slab for shear friction doesn't appear to be an option either.

I'm wondering if anyone else has come up with a great idea in the past that could be considered? Or are we kind of SOL and I'll have to tell the architect we need to bring the top of wall up to top of slab? Another idea I'm considering is to hold the top of wall down 1/4" to 1/2" and pour an overlayment on top of it to get the finish and elevation perfect. Though I don't know if that will stand up to power-troweling.

So now we have the question on how to connect the deck to the top of the wall to resist this large out-of-plane load. Headed anchors can't resist the load as the breakout is about 75% overstressed. We don't have beams framing perpendicularly into the wall at all locations so we can't use the beams either. And since we're only using a 4" total slab thickness with the metal deck, developing rebar into the slab for shear friction doesn't appear to be an option either.

I'm wondering if anyone else has come up with a great idea in the past that could be considered? Or are we kind of SOL and I'll have to tell the architect we need to bring the top of wall up to top of slab? Another idea I'm considering is to hold the top of wall down 1/4" to 1/2" and pour an overlayment on top of it to get the finish and elevation perfect. Though I don't know if that will stand up to power-troweling.