Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations dmapguru on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

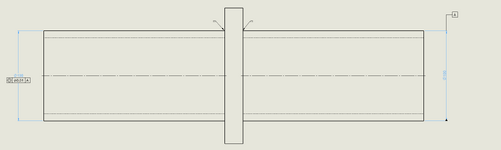

Coaxiality tolerance for the welded structures

- Thread starter SD12

- Start date

SWComposites

Aerospace

what is the issue?

the tolerance looks to be on the left hand side, referencing datum A shown on the right.

the tolerance looks to be on the left hand side, referencing datum A shown on the right.

Tolerance would depend on the application, I assume.

You could assume an offset and check resulting moments and stresses in all members to find the effect of tolerance.

Perhaps limited by cosmetics, by measuring and fit-up gear available, by tolerances in tube roundness.

You could assume an offset and check resulting moments and stresses in all members to find the effect of tolerance.

Perhaps limited by cosmetics, by measuring and fit-up gear available, by tolerances in tube roundness.

- Thread starter

- #4

Yes. But my question is about that Ø0.01 tolerance value. Is this value realistic for a welded structure?what is the issue?

the tolerance looks to be on the left hand side, referencing datum A shown on the right.

This part isn't made by machining.

- Thread starter

- #5

Hello.Tolerance would depend on the application, I assume.

You could assume an offset and check resulting moments and stresses in all members to find the effect of tolerance.

Perhaps limited by cosmetics, by measuring and fit-up gear available, by tolerances in tube roundness.

I am trying to figure out what is the realstic value for the tolerance zone that can be obtained for the welded structure of this type. To me, even Ø0.1 looks challenging to get.

As JStephen says, it depends on the application. Is it a building structure, a piping structure, a jet engine structure, etc? These all can use the same shape of components but have very different tolerances. In my field (building structures), we fabricate to 1/8" (about 3mm) of tolerance. I can see a jet engine would need a tolerance of 0.01mm (or more) in places.

SWComposites

Aerospace

is there a hole in the plate with diameter equal to pipe ID?

what is the application?

where did the drawing come from?

if it came from a customer of yours, then contact them and discuss the requirements

what is the application?

where did the drawing come from?

if it came from a customer of yours, then contact them and discuss the requirements

The 0.01mm concentricity is way too tight to be made practically. I think you might even have trouble with that if you welded this and then machined the outside diameter after, but I'm not positive. I would agree that 0.1mm would probably not be achievable with welding alone.

As others have said, you need to figure out where that tolerance came from and question why it's so tight.

As others have said, you need to figure out where that tolerance came from and question why it's so tight.

Similar threads

- Question

- Replies

- 23

- Views

- 15K

- Replies

- 8

- Views

- 14K

- Question

- Replies

- 0

- Views

- 6K

- Replies

- 1

- Views

- 467

- Question

- Replies

- 4

- Views

- 13K