Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

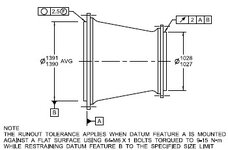

AVG and F symbol - fig 8-14/2018

- Thread starter greenimi

- Start date

- Thread starter

- #4

What do you mean by "different meaning" ?Otherwise, the roundness will have a different meaning.

In Figure 8-13 there is a single compound tolerance callout.

In Figure 8-14 there are two separate callouts.

Any "why" questions should be addressed to ASME committee members directly at the ASME Y14 committee meetings. No one but those who attend can possibly have any idea why anything is done in that group. Frankly, I have my doubts that most of them do.

In Figure 8-14 there are two separate callouts.

Any "why" questions should be addressed to ASME committee members directly at the ASME Y14 committee meetings. No one but those who attend can possibly have any idea why anything is done in that group. Frankly, I have my doubts that most of them do.

Last edited:

- Thread starter

- #8

- Thread starter

- #9

A callout for circularity shall be specified on a surface and not to a size dimension. The circularity tolerance shall be less than the size tolerance and other geometric tolerances that affect the circularity of the feature, except for those features where Rule #1 does not apply (e.g. "free state" symbol, average diameter, “independency" symbol).

From 2018 paragraph 8.4.3

Therefore do you see at least two problems here or it's just me?

One problem identified at the onset of this thread and the second being the "association" with the size in fig 8-13 (clearly forbidden per the above text).

From 2018 paragraph 8.4.3

Therefore do you see at least two problems here or it's just me?

One problem identified at the onset of this thread and the second being the "association" with the size in fig 8-13 (clearly forbidden per the above text).

Last edited:

No one but those who attend can possibly have any idea why anything is done in that group. Frankly, I have my doubts that most of them do.

Did this particular issue come up on a drawing that you are working with? Was it an actual problem?

Is the admonition to apply it to a surface anything but an arbitrary rule? Was there any confusion about what surface the circularity applied to or is it just that it appears to conflict with a rule that is made for no other reason than to have a rule?

Burunduk

Mechanical

- May 2, 2019

- 2,551

They should've just written one clear, simple rule for the whole topic of placing feature control frames. I've seen drawings where position or profile FCF was attached to a basic locating dimension. The rule should have been straightforward: attach it to a dimension only when the tolerance zone is meant to control resolved geometry like a center plane, axis, or derived median line/plane. In all other cases, when it's a surface control, the FCF should be attached to the surface representation using a leader or directly. Or to another FCF, or in a note.

The size dimension applies to the surface; there is no ambiguity.

A basic dimension used for locating a feature does not apply to a surface so whatever fever dream you are finding on drawings are very far from any sense of reason and no amount of rules will fix that.

The (F) is useful for idiot-proofing the manufacture and inspection process to ensure, by being explicit that there would be no confusion as to the status of that measurement when an AVG modifier is also in use.

It remains unclear why there is no perimeter tolerance to ensure flexible parts will fit, something that "AVG" doesn't do.

A basic dimension used for locating a feature does not apply to a surface so whatever fever dream you are finding on drawings are very far from any sense of reason and no amount of rules will fix that.

The (F) is useful for idiot-proofing the manufacture and inspection process to ensure, by being explicit that there would be no confusion as to the status of that measurement when an AVG modifier is also in use.

It remains unclear why there is no perimeter tolerance to ensure flexible parts will fit, something that "AVG" doesn't do.

Burunduk

Mechanical

- May 2, 2019

- 2,551

Is it far from any sense of reason to say that a basic dimension that locates a surface for a profile control applies to the surface?The size dimension applies to the surface; there is no ambiguity.

A basic dimension used for locating a feature does not apply to a surface so whatever fever dream you are finding on drawings are very far from any sense of reason and no amount of rules will fix that.

The (F) is useful for idiot-proofing the manufacture and inspection process to ensure, by being explicit that there would be no confusion as to the status of that measurement when an AVG modifier is also in use.

It remains unclear why there is no perimeter tolerance to ensure flexible parts will fit, something that "AVG" doesn't do.

Yet we are not supposed to attach a profile FCF to any basic dimension, it should be attached or pointing to the surface or surfaces.

Perpendicularity, parallelism or angularity has a different meaning when the FCF is associated with the size dimension. So is flatness and straightness. Having a single rule would only add clarity and consistency and make this language more accessible.

Far be it from me to make an assumption, but every basic dimension is between two surfaces/features, except for radii and diameters. Even if one end references an axis, that is the axis of a surface.

Which of the two surfaces would the tolerance apply to?

Join the committee and tell them how to do the right thing. You won't win because it's not your profession to sell training materials or to sell required upgrades to CMM software that are needed to keep in step with the latest changes that, sometimes/often contradict previous parts of the standard.

Which of the two surfaces would the tolerance apply to?

Join the committee and tell them how to do the right thing. You won't win because it's not your profession to sell training materials or to sell required upgrades to CMM software that are needed to keep in step with the latest changes that, sometimes/often contradict previous parts of the standard.

- Thread starter

- #16

You won't win because it's not your profession to sell training materials or to sell required upgrades to CMM software that are needed to keep in step with the latest changes that, sometimes/often contradict previous parts of the standard.

.........or is it just that it appears to conflict with a rule that is made for no other reason than to have a rule?

It is the latest. The checker wants to follow the rules and regulations per the applicable standard. And I don't blame him.

If what you said (......"to sell training materials or to sell required upgrades to CMM software"....) is true than is sad.

We can expect than the "forever changes" to keep ASME in bussiness.

But then, at least stay consistent with your own rules. Don't break your own imposed rule in your own created figure.

Burunduk

Mechanical

- May 2, 2019

- 2,551

But then, at least stay consistent with your own rules. Don't break your own imposed rule in your own created figure.

If we go all the way with those speculations, maybe the purpose is to have the user scratching his head and doubting his understanding, until an ASME-affiliated training provider tells him there is an error in the standard?

mfgenggear

Aerospace

As all ways I am scratching my head.

But my assumption is hollow or tube like parts are

Flimsy. And even thou are in size. Have to be

In the restrained condition. In the old days

A note was applied (inspected in the restrained condition) in the example above a fixture is required, mounted on A & B.

Thus intent it will assemble, runout acceptable.

Is this a correct assumption?

But my assumption is hollow or tube like parts are

Flimsy. And even thou are in size. Have to be

In the restrained condition. In the old days

A note was applied (inspected in the restrained condition) in the example above a fixture is required, mounted on A & B.

Thus intent it will assemble, runout acceptable.

Is this a correct assumption?

Last edited:

- Thread starter

- #20

But seriously speaking, If I'm not mistaken, the rule that a circularity FCF can't be attached to the dimension is new in 2018, while the figure is a carryover from previous versions.

Yes, I agree, but why they are doing a half-assed job?

They changed fig. 8-14 to "disconnect it" from the size (and to show the applicable circularity on the surface), but they "forgot" to remove circled F.

They changed fig. 8-13 by removing F , but they left the circularity attached/ "associated" with the size.

Go figure. Where is consistency?

And we, the end users, supposed to understand all of this.....or we suppose to pay trainers to explain the unexplainable.

Similar threads

- Replies

- 62

- Views

- 10K

- Locked

- Question

- Replies

- 1

- Views

- 311

- Locked

- Question

- Replies

- 9

- Views

- 5K

- Locked

- Question

- Replies

- 5

- Views

- 3K

- Locked

- Question

- Replies

- 6

- Views

- 620