Subhash_K

Mechanical

- Aug 1, 2024

- 6

Hey everyone,

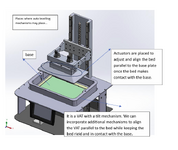

I'm working on a resin MSLA 3D printer project and exploring ways to implement an auto bed leveling system. I’m aiming for precise parallel alignment between the build plate and the resin vat to reduce peel forces and avoid print failures.

I’m looking for ideas, suggestions, or experiences related to auto-leveling mechanisms specifically for resin printers — this could include mechanical systems, sensor types, actuation methods, or even software-based solutions.

If you’ve come across or designed any interesting mechanisms or concepts, I’d really appreciate your input! Diagrams, links, or references are also welcome.

I’m working on a desktop-scale MSLA printer (about 200mm x 120mm build area). At this size, even a slight tilt or uneven pressure can cause one side to cure harder, increase peel forces, or lead to failed prints on large flat layers.

Manual bed leveling (paper test, screw adjustments) works but I’m curious about more advanced methods like: