UTvoler

Structural

- Oct 7, 2010

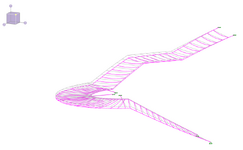

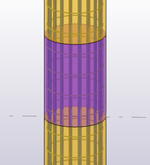

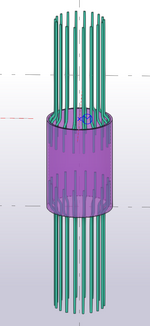

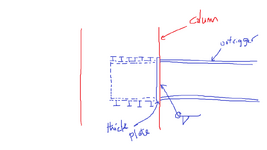

- 55

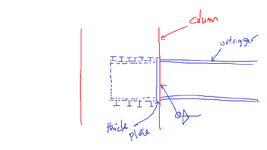

Hello all you ACI anchorage experts! I am soliciting for opinions on a fun one: I have a round CIP concrete building column supporting three W27 cantilever outrigger beams (supporting a massive ornamental stair). The outriggers will be connected to the column via an embed plate (see attached). How do we tackle the anchorage evaluation on this one (I am the delegated designer, and get to provide the calc package that shows this embed and connection is good) per ACI 318-14 (Ch. 17 presumably). I have run a simplified preliminary analysis using Profis, and it doesn't seem too far out the realm of possibility of working.

Thoughts on the approach for analysis??? I'm trying to wrap my head around the three tensile forces due to bending projecting outward in different directions from the round face; maybe some WAG combined vector of the tensile force against the capacity of the breakout of most of the column? Thanks in advance!

Thoughts on the approach for analysis??? I'm trying to wrap my head around the three tensile forces due to bending projecting outward in different directions from the round face; maybe some WAG combined vector of the tensile force against the capacity of the breakout of most of the column? Thanks in advance!