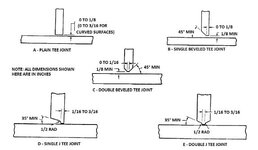

Depending on the strength needed, there are different types of tee joint welds that can be used. The main types of Tee-Joints are:

a)Plain Tee-Joint,

b)Single Beveled Tee-Joint,

c)Double Beveled Tee-Joint,

d)Single-J Tee Joint,

e)Double-J Tee Joint.

For Welding Procedures Specifications(WPS) of plain Tee-Joint, A qualified WPS based on test piece with fillet welds could be used to welding of plain Tee-Joint.

So, if I want to weld beveled Tee-Joint(Single Beveled Tee-Joint, Double Beveled Tee-Joint, Single-J Tee Joint, Double-J Tee Joint), what type of test piece should be prepared and what tests should be conducted?

Thank you.

a)Plain Tee-Joint,

b)Single Beveled Tee-Joint,

c)Double Beveled Tee-Joint,

d)Single-J Tee Joint,

e)Double-J Tee Joint.

For Welding Procedures Specifications(WPS) of plain Tee-Joint, A qualified WPS based on test piece with fillet welds could be used to welding of plain Tee-Joint.

So, if I want to weld beveled Tee-Joint(Single Beveled Tee-Joint, Double Beveled Tee-Joint, Single-J Tee Joint, Double-J Tee Joint), what type of test piece should be prepared and what tests should be conducted?

Thank you.