I’m working on a low-rise apartment project where the foundation will be supported by piles. Due to poor soil conditions (sand) and a high water table, the required pile length exceeds 15 meters.

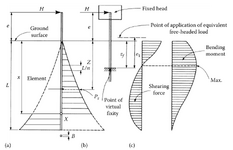

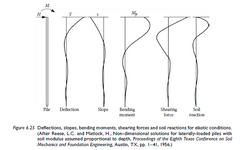

I’m considering using CFA piles, with heavier reinforcement concentrated in the upper (about 0–7 meters) to resist lateral loads, and lighter reinforcement below that depth. Is it weird/unconventional to reinforce piles this way, or is this a common approach? Would you recommend any more cost-effective alternatives?

Do you also have any advice for managing groundwater, particularly during the construction phase?

Thank you.

I’m considering using CFA piles, with heavier reinforcement concentrated in the upper (about 0–7 meters) to resist lateral loads, and lighter reinforcement below that depth. Is it weird/unconventional to reinforce piles this way, or is this a common approach? Would you recommend any more cost-effective alternatives?

Do you also have any advice for managing groundwater, particularly during the construction phase?

Thank you.