canwesteng

Structural

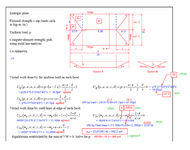

I'm having a brain fart here, and no one in my office is terrific with yield lines. Normally I take the yield line mechanism of a flat plate (fixed support in this case) to be the red line, with the diagonals at 45 degrees. However, the project length about the horizontal of the diagonal yield lines decreases the steeper they get and the vertical projection doesn't change. So the steeper these get the weaker the mechanism, though this seems irrational. It is simple to just call the diagonals 45 degrees in the case of reinforcement equal in each direction, but in this case the short side has less reinforcement than the strong side, so it must be somewhat steeper than 45. Is there something I'm missing?