Hi all, currently im designing a blind flange (28") for an LPG storage tank based on the asme sect 8 Div 1.

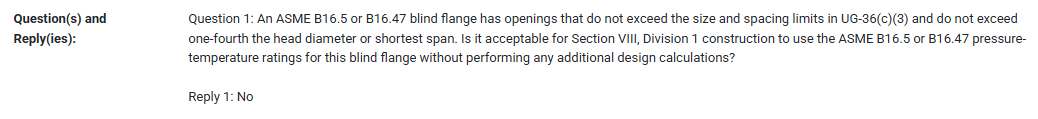

The blind flange had two threaded opening, 2" npt and 1-1/4" npt. Based on UG-36, i understand that this size of opening do not required reinforcement calc. Does this mean that i can just proceed this opening on the ANSI 300 28" blind flange?

Hope someone can help me on this. tq

The blind flange had two threaded opening, 2" npt and 1-1/4" npt. Based on UG-36, i understand that this size of opening do not required reinforcement calc. Does this mean that i can just proceed this opening on the ANSI 300 28" blind flange?

Hope someone can help me on this. tq