Hi All,

I think this may be an easy answer for a tank designer. I found a few other threads with similar questions, but didn't see an answer.

On water tank projects, our company would typically provide the civil engineering and the foundation design. However, the tank design is a delegated design by the contractor/tank manufacturer.

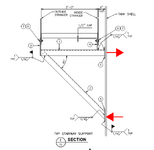

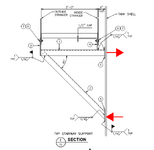

The calculation submittal will have calculations for the various appurtenances, such as stairways and guardrails. They are usually very complete, but they never check the stress on the tank shell.

Is this just considered to be not required? Is this a case where the loads are so small compared to the normal loading on a tank that it doesn't need to be checked? Or have they checked it so many times before that they know it will work? I did look in AWWA D100 and API 650 and didn't see specific design guidance.

Does anyone know if there are simple checks for plate stress that can be done?

Thanks for any help.

I think this may be an easy answer for a tank designer. I found a few other threads with similar questions, but didn't see an answer.

On water tank projects, our company would typically provide the civil engineering and the foundation design. However, the tank design is a delegated design by the contractor/tank manufacturer.

The calculation submittal will have calculations for the various appurtenances, such as stairways and guardrails. They are usually very complete, but they never check the stress on the tank shell.

Is this just considered to be not required? Is this a case where the loads are so small compared to the normal loading on a tank that it doesn't need to be checked? Or have they checked it so many times before that they know it will work? I did look in AWWA D100 and API 650 and didn't see specific design guidance.

Does anyone know if there are simple checks for plate stress that can be done?

Thanks for any help.