Hi,

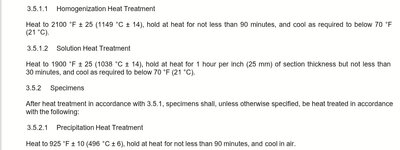

I'm currently making a development about 17-4PH investment casting but I have some doubts about separately cast specimens for tensile and impact tests. Can I heat treated these specimens (diameter of 6.35 mm) in the same charge of pieces of castings? or do i need heat treated the separately cast specimens in different charge? The pieces of casting have a thickness of 2 1/2 inches and a weight of 35 kg.

another question is do i need using an atmosphere such as vacuum, argon or nitrogen? or Can i use a furnace without controlled atmosphere for this material?

Regards.

I'm currently making a development about 17-4PH investment casting but I have some doubts about separately cast specimens for tensile and impact tests. Can I heat treated these specimens (diameter of 6.35 mm) in the same charge of pieces of castings? or do i need heat treated the separately cast specimens in different charge? The pieces of casting have a thickness of 2 1/2 inches and a weight of 35 kg.

another question is do i need using an atmosphere such as vacuum, argon or nitrogen? or Can i use a furnace without controlled atmosphere for this material?

Regards.