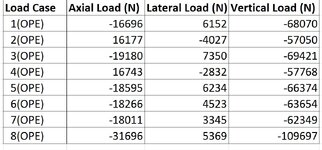

I have a query that I need some advice on. I am checking the bearing capacity of pad foundations supporting an above-ground pipeline. The pipeline team have provided loads, which include an axial load along the longitudinal axis of the pipe, a lateral load and a vertical load. The civil engineer advised me to apply an overturning moment caused by the axial load (lever arm of 1m) which causes a very large load eccentricity significantly reducing the effective breadth of the foundation. The pad foundations are typically quite small (1m x 1m x 0.5m deep) and therefore I am sceptical that the axial load would induce such a large moment. The lateral loads in the direction perpendicular to the pipeline are relatively small and are not an issue in terms of eccentric loading. Instead, would the axial load not transfer a frictional load to the foundation?

Any advice would be greatly appreciated.

Any advice would be greatly appreciated.