Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations MintJulep on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

choke valve

- Thread starter 142846

- Start date

- Status

- Not open for further replies.

- Thread starter

- #3

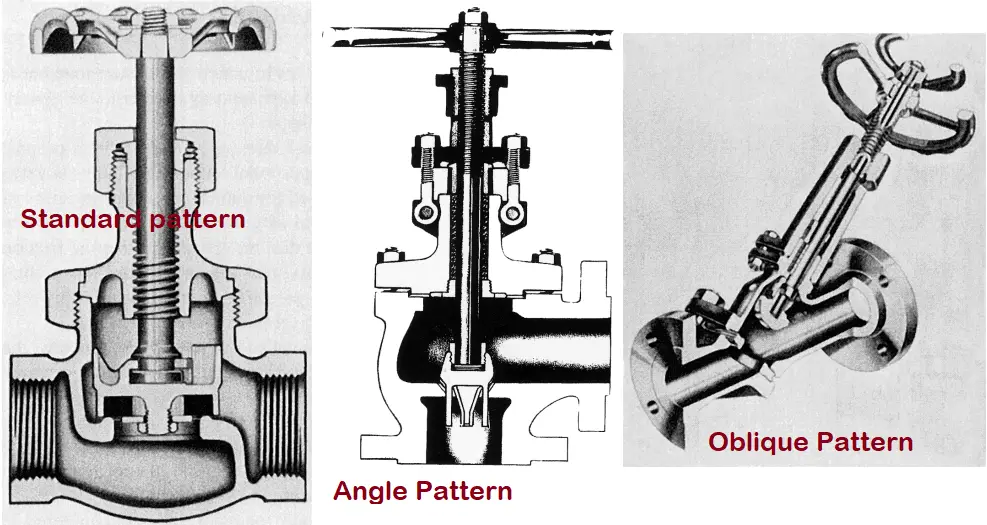

An oil/gas well choke valve is configured to connect conveniently to the well head with a 90° angle connecting to downstream piping.

Functionally it is just a plug valve or angle valve that is adapted for extremely high pressure drop. Note that the flow direction is opposite to the choke valve.

High pressure strength, temperatures, mechanical strength, durability, reliability and tight shutoff characteristics as well as noise control and ease of maintenance should all be considered. A common plug valve would not work in a typical oil/gas field, but if you made the right adaptions, then you would have a very expensive choke valve that probably would not work for very long.

Functionally it is just a plug valve or angle valve that is adapted for extremely high pressure drop. Note that the flow direction is opposite to the choke valve.

High pressure strength, temperatures, mechanical strength, durability, reliability and tight shutoff characteristics as well as noise control and ease of maintenance should all be considered. A common plug valve would not work in a typical oil/gas field, but if you made the right adaptions, then you would have a very expensive choke valve that probably would not work for very long.

LittleInch

Petroleum

my question

Is choke valve function is same as converge nozzle or converge-diverge nozzle?

No. Nothing like it. It's designed to reduce pressure at very high pressure drop three phase fluid.

can we reach to sonic velocity in chock valves?

Yes but they try not to as it means you've achieved choked flow, which is not what you want. And it makes it very noisy. Hence the aim with the cage is to have lots of multiple pressure drops and to increase surface area as it needs for more flow.

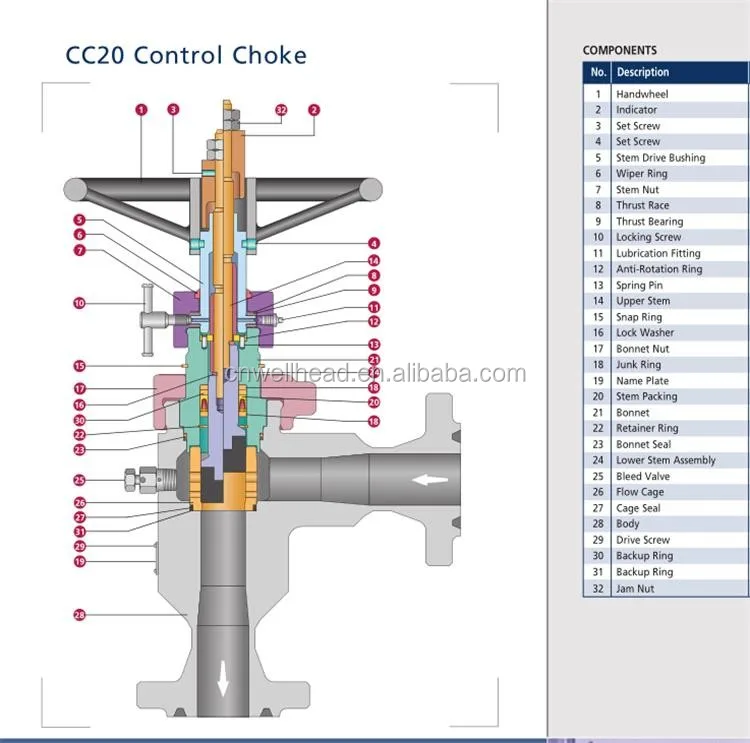

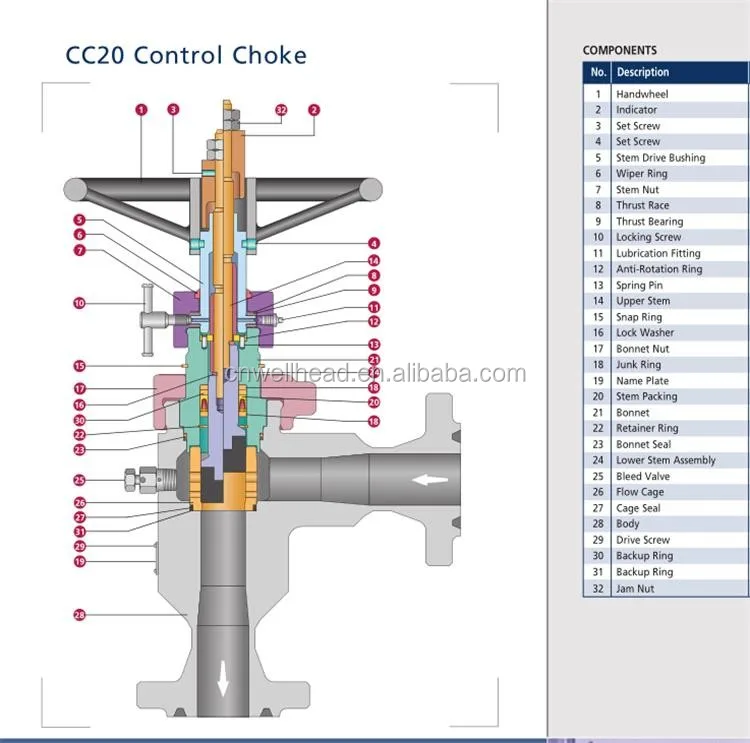

As Mr 44 says, flow in plug and cage chokes goes outside to in so that the very high velocity jets hit each other in the centre of the cage and cancel each other out rather than erode a hole in the valve casing.

thanks for any comments.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

- Thread starter

- #6

For reducing the pressure drop there are some mechanism such as restriction orifice or nozzle and ... my question is which mechanism is governing?No. Nothing like it. It's designed to reduce pressure at very high pressure drop three phase fluid.

I think cc20 choke valve is very similar to converge-diverge orifice. Am I right?1503-44 (Petroleum)

If somebody asked us what is two difference between globe vale and choke valve, what is the answer? *except metallurgy". because both valves regulate flow and there are globe valves that could be installed at high delta pressure process.

LittleInch

Petroleum

Restriction orifice(s) are your key pressure reduction.

A CC20 choke is not a converge diverge nozzle.

Differences?

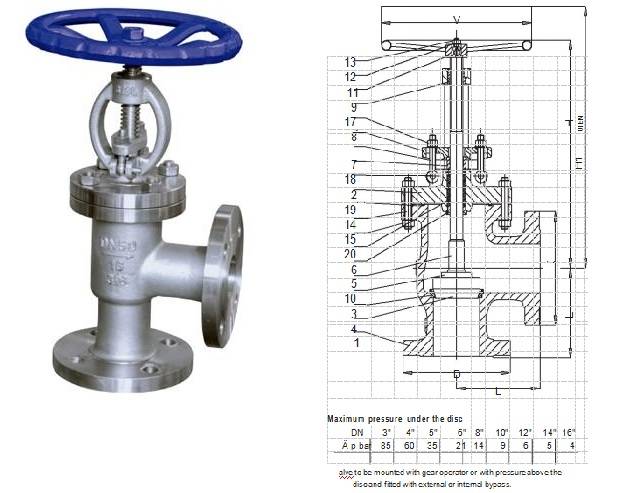

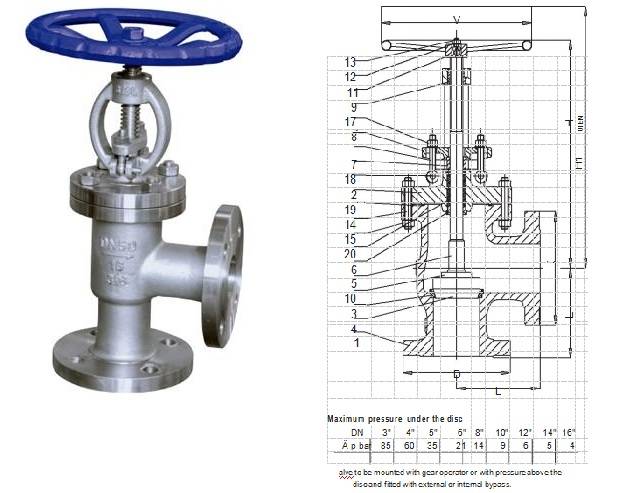

Choke valve are normally flow outside of a cage into the inside, globe tends to be flow up into a moving central plug / cone / disc.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

A CC20 choke is not a converge diverge nozzle.

Differences?

Choke valve are normally flow outside of a cage into the inside, globe tends to be flow up into a moving central plug / cone / disc.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

What are you trying to use this information for? This answer will steer the responses to you query.

Choke trim is generally referred to by orifice size. You will not find an exact mechanism to simplify the behavior of all chokes. The most dominant effect in chokes will however be the orifice restriction. Looking at the cross section of the the cc20 above the flow path the fluid will take is a change in direction around the gallery followed by flow separation and an orifice restriction in the cage, an impingement with other flow streams and then a 90 degree change in direction. This is obviously a more complicated process than orifice/nozzle flow.

That is similar to asking what the difference between a gate valve and a ball valve is. The functionality of both vales is to provide a positive shutoff, but the devil is in the details. The globe vale is not setup to take high pressure drops. As explained earlier the flow over stem design creates impingent with the body wall which will cause erosion damage at high DP with clean fluids or low to moderate DP with fluids which contain abrasives. A choke avoids this body erosion almost entirely, and also has removable seats which are designed to be field replaceable as they are considered wear items. Many globe vales have a hard-faced seating surface which requires machining to repair. There are significant differences in required actuation forces as well.

For general purposes globe valves will have a higher pressure recovery than a choke.

The level of differential pressure able to be generated is also different. On the process side of things pressures are much lower than the production side where chokes dominate. Some specialized high pressure chokes are capable of producing a 10-15Ksi pressure drop with a 20-30Ksi design pressure. You wont find that type of functionality in a globe valve.

142846 said:For reducing the pressure drop there are some mechanism such as restriction orifice or nozzle and ... my question is which mechanism is governing?

Choke trim is generally referred to by orifice size. You will not find an exact mechanism to simplify the behavior of all chokes. The most dominant effect in chokes will however be the orifice restriction. Looking at the cross section of the the cc20 above the flow path the fluid will take is a change in direction around the gallery followed by flow separation and an orifice restriction in the cage, an impingement with other flow streams and then a 90 degree change in direction. This is obviously a more complicated process than orifice/nozzle flow.

142846 said:If somebody asked us what is two difference between globe vale and choke valve, what is the answer? *except metallurgy". because both valves regulate flow and there are globe valves that could be installed at high delta pressure process.

That is similar to asking what the difference between a gate valve and a ball valve is. The functionality of both vales is to provide a positive shutoff, but the devil is in the details. The globe vale is not setup to take high pressure drops. As explained earlier the flow over stem design creates impingent with the body wall which will cause erosion damage at high DP with clean fluids or low to moderate DP with fluids which contain abrasives. A choke avoids this body erosion almost entirely, and also has removable seats which are designed to be field replaceable as they are considered wear items. Many globe vales have a hard-faced seating surface which requires machining to repair. There are significant differences in required actuation forces as well.

For general purposes globe valves will have a higher pressure recovery than a choke.

The level of differential pressure able to be generated is also different. On the process side of things pressures are much lower than the production side where chokes dominate. Some specialized high pressure chokes are capable of producing a 10-15Ksi pressure drop with a 20-30Ksi design pressure. You wont find that type of functionality in a globe valve.

- Status

- Not open for further replies.

Similar threads

- Locked

- Question

- Replies

- 13

- Views

- 1K

- Replies

- 15

- Views

- 2K

- Replies

- 0

- Views

- 199

- Locked

- Question

- Replies

- 4

- Views

- 472

- Replies

- 0

- Views

- 177