I'd say

1) soft seats are OK for a trap

2) Maybe not use a trunnion valve for sizes of 6", or 8", or less

3) and I'd change "normally you would need double ball valves" to "you would not need double" valves

There is no design code, standard practice, recommended practice, or anything else, except a few company standards and those companies that like to copy other company standards and make them thier own, that require doubled ball valves for isolation (in non-poisonous, hydrocarbon service), although a few oil/gas production companies (I personally only know of about 4, maybe 5, in the whole world) who do seem to think that they need it for some reason.

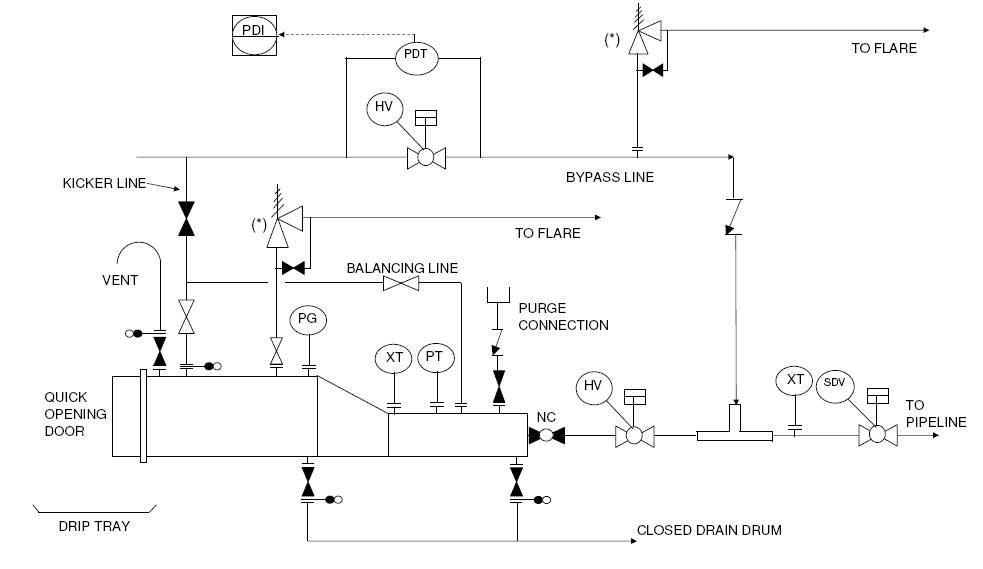

To make it clear, what I'm talking about is shown here in this PID, the two valves being the ones at the end of the launcher barrel, with the operator notation "NC", and "HV".

Interestingly enough those companies that do use doubled valves do not agree even to the slightest extent about when they need double valves. Some say everything over 10 barg, another not until 100 barg.

While there may be a few oil and gas production companies that do use doubled valves, I don't know of any "pipeline" transmission companies (in any country) that would even think of using double valves at a launcher, or anywhere else for that matter. Does anyone know of any

pipeline companies that work to a double-valve isolation standard ie. putting two valves between launcher and pipeline? I'd be interested in knowing what others might think. Which companies (production, or pipeline) do this?

As far as that PID goes, any other comments about this PID?

I would not think a PSV is necessary for a gas line, although the bypass to flare might be helpful sometimes. A thermal expansion relief could be needed for a liquid line, but only if the trap barrel was left in a full condition. Why it would, I don't know.

I don't think balancing lines are necessary.

Why two drains?

The PSV might be a good idea, if someone hooked up a high pressure source to the purge connection. There was a fatal accident like that 2 years ago.

I've never had a necessity to put a check valve in the bypass line.

The second XT, assume it's a pig sig, on the pipeline, might be underground in many onshore configurations.

I would not normally put an ESD on the pipeline (the third valve there), as I know that ESD valves should isolate station from pipeline, but in production situations, especially offshore, an ESD "emergency shut down", or SDV "shut down valve" for those not willing to admit to the possibility of an emergency situation, is often placed on the pipeline riser to try to stop gas backflow near the topside decks.

I hate Windowz 8!!!!

![[dazed] [dazed] [dazed]](/data/assets/smilies/dazed.gif)