Hi all,

I'm currently working on reverse engineering an aviation fuel valve to troubleshoot and eliminate recurring leakage issues.

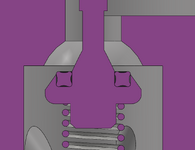

As shown in the attached image, the primary suspect is the X-ring, which sits in a groove on the poppet.

I have limited experience with X-rings, but I suspect the current design may be suboptimal.

Specifically, the geometry of the sealing face seems poorly matched to the X-ring.

The curved profile doesn't appear to provide proper "geometry" for sealing with an X-ring, and I believe a flat, perpendicular sealing face (relative to the axial motion of the poppet) would offer more consistent and reliable sealing.

In addition, the fact of the matter is that the spring applying force to the poppet, and thus to the X-ring against the sealing face, is relatively weak, which may further compromise sealing performance.

Another issue I have with this assembly is that the instructions dictates that the seal must be glued using Loctite 495, which is brittle when dried; what reasoning might lead to using a brittle glue to bond a soft/elastic material in its groove?

I'd appreciate any insights on X-ring use in face-sealing applications, and whether this setup aligns with best practices.

Best,

SD