medeek

Structural

- Mar 16, 2013

- 1,104

A couple simple questions with Woodworks software for all the Woodworks gurus.

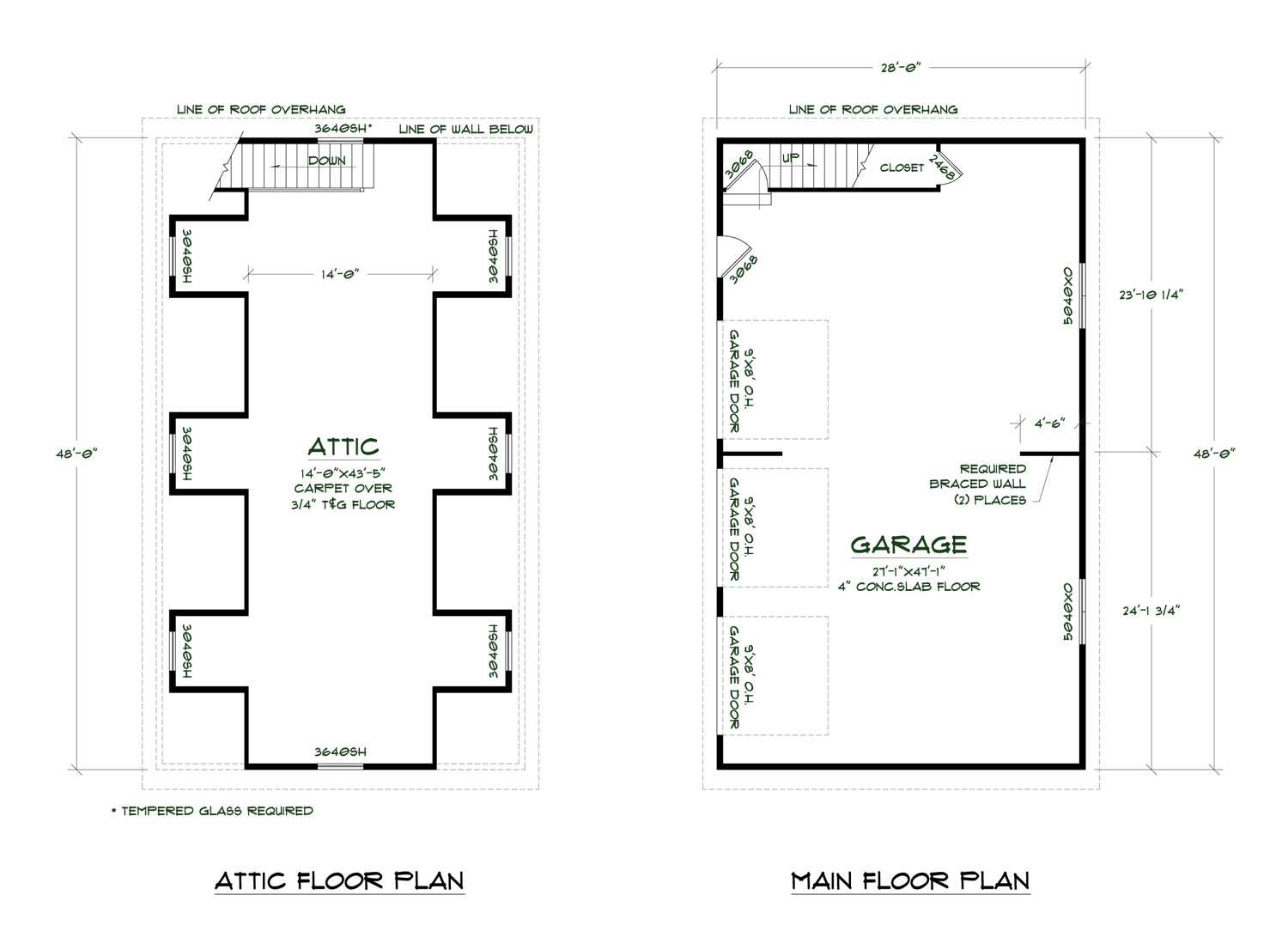

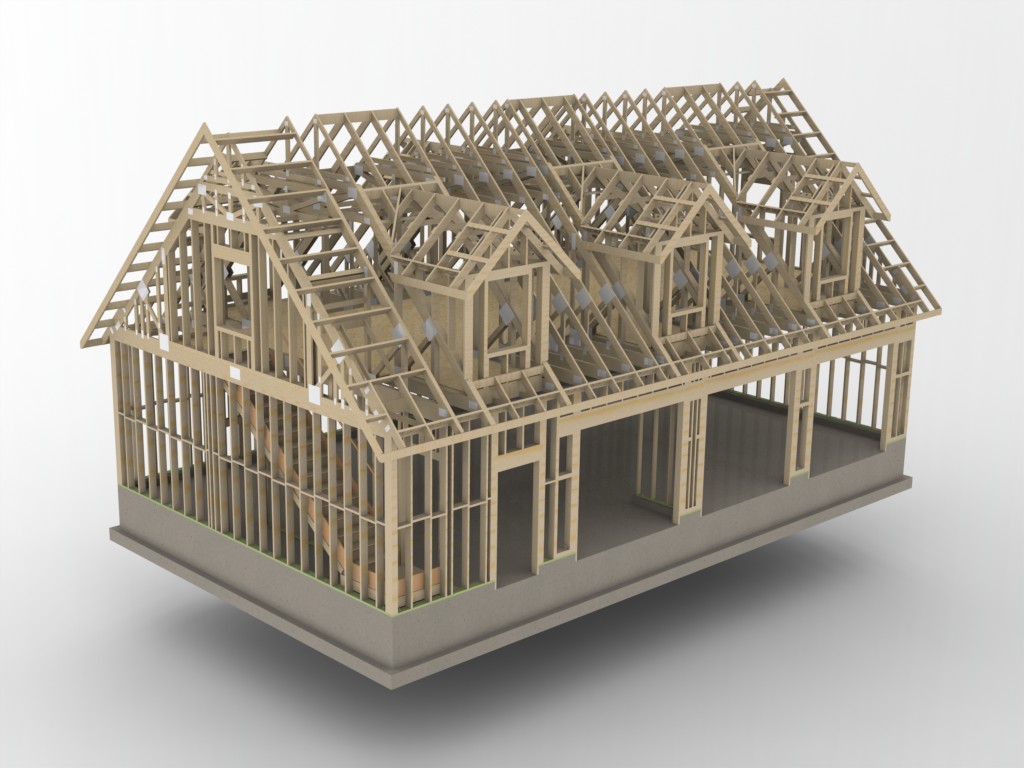

1.) I have a small 12/12 gable roof framed with attic trusses. What is the best way to model this in the software in order to accurately model seimic dead loads from the attic floor space?

2.) Same roof line as above except now I've got a shed dormer (approx. 8ft high) on one side of the gable roof with a 3/12 pitch.

A confused student is a good student.

1.) I have a small 12/12 gable roof framed with attic trusses. What is the best way to model this in the software in order to accurately model seimic dead loads from the attic floor space?

2.) Same roof line as above except now I've got a shed dormer (approx. 8ft high) on one side of the gable roof with a 3/12 pitch.

A confused student is a good student.