Hello everyone. Why are intermittent groove/butt welds prohibited, with either full or partial penetration? This is specified in the European design code (Eurocode 3). I am not familiar with other standards, but I see this is also specified in AWS D1.1 (4.8.2). Please correct me if I misunderstand. I'm not looking at a particular connection (example), just the reasoning behind it (in principle). Does is have anything to do with the type of loads applied (static or dynamic), fatigue etc. Thank you in advance.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why are intermittent groove/butt welds prohibited? 3

- Thread starter SSM_27

- Start date

- Status

- Not open for further replies.

Not contradicting, but when you bevel the weld surface, I generally consider that as a prepared weld, not a butt or fillet. I'd consider the weld below as a prepared weld, not a butt.

-----*****-----

So strange to see the singularity approaching while the entire planet is rapidly turning into a hellscape. -John Coates

-Dik

-----*****-----

So strange to see the singularity approaching while the entire planet is rapidly turning into a hellscape. -John Coates

-Dik

Kingnero,

IMHO you are fine with what you are doing.

You have supplied info referencing ISO/EU codes / standards which are the codes / standards which are applicable to your work so that is all that matters.

r6155 has referenced AWS D1.1 and in that respect he is correct.

AWS D1.1 and AWS 3.0 (Terms & Definitions) state a butt joint is in approximately the same plane.

They both also state a "butt weld" is a non-standard term for a weld in a "butt joint".

So they are not Butt welds as per AWS.

Cheers,

Shane

IMHO you are fine with what you are doing.

You have supplied info referencing ISO/EU codes / standards which are the codes / standards which are applicable to your work so that is all that matters.

r6155 has referenced AWS D1.1 and in that respect he is correct.

AWS D1.1 and AWS 3.0 (Terms & Definitions) state a butt joint is in approximately the same plane.

They both also state a "butt weld" is a non-standard term for a weld in a "butt joint".

So they are not Butt welds as per AWS.

Cheers,

Shane

0707 said:This question makes no sense.

Thanks for your valuable input.

The devil is in the details; she also wears prada.

dik said:Not contradicting, but when you bevel the weld surface, I generally consider that as a prepared weld, not a butt or fillet. I'd consider the weld below as a prepared weld, not a butt.

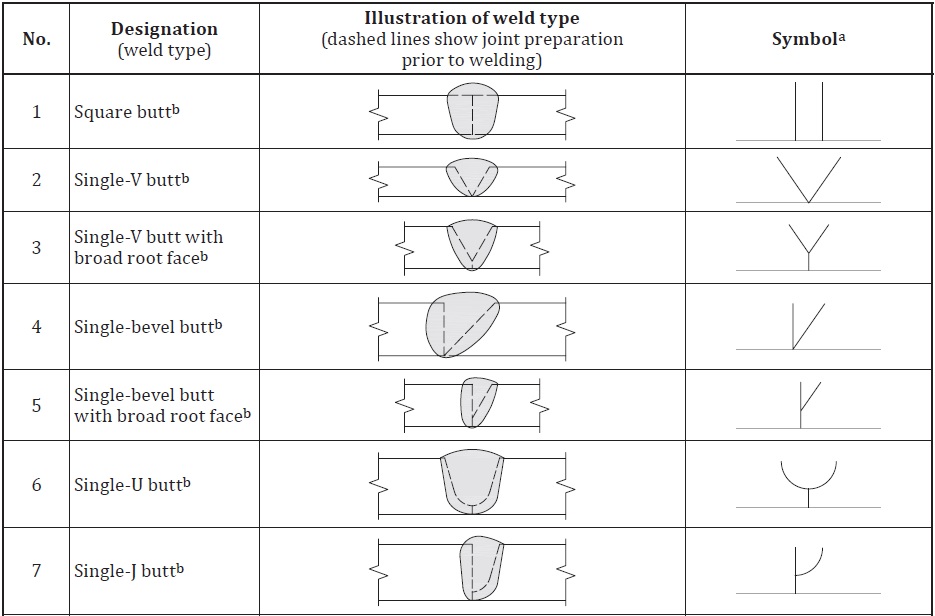

So, in the below table, you'd only call #1 a butt weld? The others are "prepared welds"?

I hope we can agree all of these are butt welds.

Footnote b:

Butt welds are full penetration unless otherwise indicated by dimensions on the welding symbol or by reference to other information, for example the WPS.

The OP mentioned Eurocodes as well. Hence my reply (with no ambiguity regarding the referenced codes or standards).DekDee said:r6155 has referenced AWS D1.1

A full penetration butt weld in a T shape, will also have 100% joint efficiency (if you are talking mechanical strength). I do agree that NDT won't be as straightforward here, as when both plates are in the same plane.r6155 said:When someone says butt weld I think of joint efficiency and NDE (RT and UT). But I can't think the same with the T-weld according to the European codes. I prefer the definition of butt weld according to ASME.

80-90% of my work is according to ISO codes (including eurocodes), so my thinking automatically goes according to the above mentioned standards. I do acknowledge that ASME has another point of view regarding to those terms. Newer ISO standards have been modified/are being modified to follow AWS and ASME more closely, however a full integration won't be for anyday soon...

The one thing that strikes me as odd the most, is that there are almost no references to partial penetration butt welds under ISO. All ISO codes automatically assume you have to weld 2 plates for their complete thickness. If you want to qualify a partial pen weld under ISO, you will have to use a standard that is made for deviations to "normal" situations. Seal welds (I despise the name), partial pen, specific geometries, are some examples that need to be qualified as "deviations to the rule".

Greetings.

Many reasons about intermittent welds are becouse that they carry insignificant amount of load and they are there just to hold the material together.

each start and end of a weld is a imperfection that is a crack and cracks grow in dynamic loads pretty quick. CTOD factor.

when a two parts are joined together with butt weld ( head to head weld) a weld that both pieces has same thickness and purpose is to generate linear structure from two pieces is that carry load.

When there is load carry weld becomes the weakest by using intermittent which many of the standard will not allow. This is the main reason why buttwelds are not done in intermittent way.

however it is possible to make intermittent buttwelds but you will not see them in acceptance of standards due to such works will be non engineering works such as decoration.

In beams some intermittent used on some places but not in buttwelds. Main reason is that the some parts carry moment and some parts of the beam carry shear ,also type of load can be dynamic and static. The parts that require to be buttwelded are the parts that carry both dynamic and static loads and the reason beam selected for that size is that it will have enough strength to carry that load. Therefore when you are doing intermittent weld to a place that require to carry load you are basically killing the load capacity of the beam. in construction beams are loaded to like %98 loads in the calculation. putting intermittent weld to a place that transfer stress will sure cause the system to fail in this kind of situation.

when it comes to intermittent welds in beams the parts you see there does not carry direct loads but they are there to increase moment of inertia to increase the stability of the beam such as preventing buckling. Thus they do not carry load but they are there to be there so the inertia of the main load carrying part of the beam will be high and it will not bucke.

I hope i was able to explain the idea behind of it.

IWE EWE certificate holder.

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 13

- Views

- 10K

- Question

- Replies

- 4

- Views

- 623

- Locked

- Question

- Replies

- 3

- Views

- 1K

- Locked

- Replies

- 5

- Views

- 5K

- Locked

- Question

- Replies

- 3

- Views

- 747