All,

So last year I posted a question re: how to resolve white rust on interior sheet metal duct wall. That thread has been closed, but here is the link:

www.eng-tips.com

www.eng-tips.com

I recommended to the owner that the Contractor shall line the ductwork with new, un-blemished G90 sheetmetal. The owner supported us (our firm), and they completed that work on (1) of the AHU's end of last year. Fast forward several months, and the completion of this task (on the other AHU) has been a topic on our weekly task list discussion ever since. Until yesterday; when the Contractor advised that it was done. I asked them how they did it. Silence for several seconds. Then the Contractor Field Foreman (not the Project Manager, who was sitting next to him) said that one of their (the Contractor's) consultants (not an engineer, but more a Project Manager) advised that they could just paint it with spray galvanizing. So they did. I'm assuming they went to ACE hardware, bought a dozen cans of spray galvanizing, and applied over all the white rust. I was speechless. Photos from earlier thread below. I have requested the Contractor provide me with details of exactly what product they used.

from earlier thread for context:

from earlier thread for context:

So. Just to reiterate. This location is the Supply Air plenum, downstream of the final MERV 14 filters in a 30,000 CFM AHU, serving the core area of a hospital. My concern expressed in the earlier thread was that while spray galvanizing works fine - on a welded hitch or the underside of your car - I can find no references for the suitability of applying this to the inside of ductwork, let alone ductwork serving a Hospital.

My concerns are mainly:

1. Surface prep. Due to the difficulty of working within this plenum, I would hazard a guess that they just sprayed the galvanizing over the white rust. From my experience, spray galvanizing only works well when applied to bare metal. Will parts eventually flake off and be sent down the ductwork to be discharged out the Supply Air grilles into the breathable environment and deposited on horizontal surfaces? My guess would be yes, eventually. Next month? Next Year? Several years? No matter the timeline, it WILL happen; at which point the AHU will need to be turned off, apply new G90 steel, then ALSO clean the downstream ductwork to eliminate the contaminants... This would be weeks of work, at least...

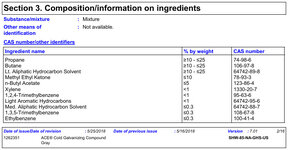

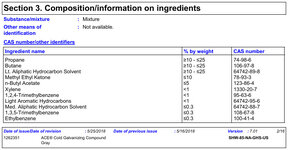

2. The additional components being added to the spray-can to make it sprayable are...nasty. Will these eventually slough-off and be mixed with the airstream? My guess would also be yes. From the MSDS on an ACE Spray Galvanizing can:

Oddly enough, the MSDS on this can does not say anything about zinc purity or other compounds... ??? Not sure how that happens, but I have to assume it is close to the label at 92%...

At this point, I am waiting for them to get back to me with the exact spray galvanizing they used. Although I do not think the particulars of another brand will change the underlying problem. In my opinion, this stuff has no place inside an air duct; let alone for use inside a hospital, and downstream of the final filters. My recommendation to the owner is to require the Contractor to resolve this properly, which would entail another G90 layer of sheetmetal to cover and encapsulate this chemical soup, and prevent it from sloughing off into the downstream ductwork and entering what is supposed to be a reasonably sterile - or at least, uncontaminated-by-heavy-metals environment.

What a pita. If they push back (which I expect), my next move would be to get an industrial hygienist involved... I think.

Thoughts?

TIA.

So last year I posted a question re: how to resolve white rust on interior sheet metal duct wall. That thread has been closed, but here is the link:

How to resolve white rust issues inside ductwork? - HVAC/R engineering

I am helping a client commission some medium sized (34,000 CFM) chilled water AHU's that were installed several years ago, but never started. This is in a hospital, on an island with lots of rain and high humidity. In cutting into a large (10 ft x 3ft) vertical SA plenum in order to get to some...

I recommended to the owner that the Contractor shall line the ductwork with new, un-blemished G90 sheetmetal. The owner supported us (our firm), and they completed that work on (1) of the AHU's end of last year. Fast forward several months, and the completion of this task (on the other AHU) has been a topic on our weekly task list discussion ever since. Until yesterday; when the Contractor advised that it was done. I asked them how they did it. Silence for several seconds. Then the Contractor Field Foreman (not the Project Manager, who was sitting next to him) said that one of their (the Contractor's) consultants (not an engineer, but more a Project Manager) advised that they could just paint it with spray galvanizing. So they did. I'm assuming they went to ACE hardware, bought a dozen cans of spray galvanizing, and applied over all the white rust. I was speechless. Photos from earlier thread below. I have requested the Contractor provide me with details of exactly what product they used.

from earlier thread for context:

from earlier thread for context:So. Just to reiterate. This location is the Supply Air plenum, downstream of the final MERV 14 filters in a 30,000 CFM AHU, serving the core area of a hospital. My concern expressed in the earlier thread was that while spray galvanizing works fine - on a welded hitch or the underside of your car - I can find no references for the suitability of applying this to the inside of ductwork, let alone ductwork serving a Hospital.

My concerns are mainly:

1. Surface prep. Due to the difficulty of working within this plenum, I would hazard a guess that they just sprayed the galvanizing over the white rust. From my experience, spray galvanizing only works well when applied to bare metal. Will parts eventually flake off and be sent down the ductwork to be discharged out the Supply Air grilles into the breathable environment and deposited on horizontal surfaces? My guess would be yes, eventually. Next month? Next Year? Several years? No matter the timeline, it WILL happen; at which point the AHU will need to be turned off, apply new G90 steel, then ALSO clean the downstream ductwork to eliminate the contaminants... This would be weeks of work, at least...

2. The additional components being added to the spray-can to make it sprayable are...nasty. Will these eventually slough-off and be mixed with the airstream? My guess would also be yes. From the MSDS on an ACE Spray Galvanizing can:

Oddly enough, the MSDS on this can does not say anything about zinc purity or other compounds... ??? Not sure how that happens, but I have to assume it is close to the label at 92%...

At this point, I am waiting for them to get back to me with the exact spray galvanizing they used. Although I do not think the particulars of another brand will change the underlying problem. In my opinion, this stuff has no place inside an air duct; let alone for use inside a hospital, and downstream of the final filters. My recommendation to the owner is to require the Contractor to resolve this properly, which would entail another G90 layer of sheetmetal to cover and encapsulate this chemical soup, and prevent it from sloughing off into the downstream ductwork and entering what is supposed to be a reasonably sterile - or at least, uncontaminated-by-heavy-metals environment.

What a pita. If they push back (which I expect), my next move would be to get an industrial hygienist involved... I think.

Thoughts?

TIA.