JStructsteel

Structural

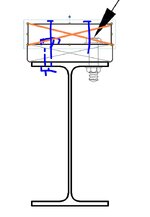

When replacing a load bearing wall with a steel beam, how thick of a top plate on the beam do you use? I have used just a single 2x before, but had a few contractors ask if they can do a double top plate.

For a roof, I get it to nail any uplift brackets. For a floor, any advantage other than fastening?

What do you folks spec?

Usually I thru bolt too with 1/2" bolts on a staggered pattern, 18" o.c.

For a roof, I get it to nail any uplift brackets. For a floor, any advantage other than fastening?

What do you folks spec?

Usually I thru bolt too with 1/2" bolts on a staggered pattern, 18" o.c.