Hello,

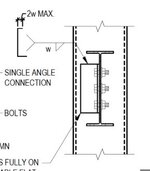

I have to design a connection of steel beam (wide flange) to a existing RCC column, refer attached photo to get the idea of what I am trying to do. For the design of end plate, I am thinking of designing it like a simple base plate of a column subjected to moment and horizontal force. Is it right or do I have to consider something else? Also please advice anything useful regarding such connections.

Thanks.

I have to design a connection of steel beam (wide flange) to a existing RCC column, refer attached photo to get the idea of what I am trying to do. For the design of end plate, I am thinking of designing it like a simple base plate of a column subjected to moment and horizontal force. Is it right or do I have to consider something else? Also please advice anything useful regarding such connections.

Thanks.