We are evaluating the design of an excavation system and looking for some feedback on the LTB stability bracing requirement for a Waler Beam.

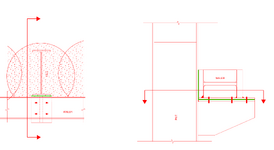

The excavation system consists of Secant walls that are braced by two levels of Waler and Corner Strut System. (image 117).

The load path is that the secant walls load the walers and the struts help redistribute the loads between the walers as axial and bending.

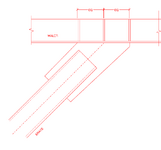

The Corner compression Struts are connected to the Waler Flanges with a gusset plate. (image 118)

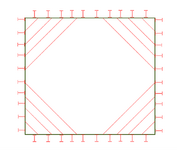

The Waler is sitting on a steel corbel and bears on the face of the Steel Pile. (image 119) It is assumed that the axial load from the waler is not transferred to the piles.

In general, for a beam subjected to compression, we provide a beam brace by either bracing the flange subject to compression directly or prevent twist of the cross section.

The Question I have is:

The excavation system consists of Secant walls that are braced by two levels of Waler and Corner Strut System. (image 117).

The load path is that the secant walls load the walers and the struts help redistribute the loads between the walers as axial and bending.

The Corner compression Struts are connected to the Waler Flanges with a gusset plate. (image 118)

The Waler is sitting on a steel corbel and bears on the face of the Steel Pile. (image 119) It is assumed that the axial load from the waler is not transferred to the piles.

In general, for a beam subjected to compression, we provide a beam brace by either bracing the flange subject to compression directly or prevent twist of the cross section.

The Question I have is:

- Can the Strut to Waler connection (with web stiffeners) on the center of flange be considered to provide stability against buckling?

- Can the Waler to Pile bearing connection (ignoring the erection bolts) be considered to provide stability against buckling?

- If additional stability bracing is required, would it need to be designed for 2% (as per CSA) of the compressive force in the member or in the flange since we are trying to brace the flanges? and If yes, can we rationalize the compression force in the flange based on its area?

- The Waler is bolted to the steel corbel but allowed to slide with long slotted holes. If the bolt group needs to be designed to resist the twist, can these bolts in the sliding bearing condition, be allowed to take tensile forces?