YuJie_PV

Mechanical

- Jan 19, 2017

- 152

hi all experts,

i am looking at para.5.4 of 2023 asme VIII-2, and have some questions regarding the buckling analysis, please shed me some light:

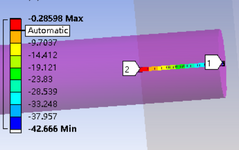

1. "if the applied loading results in a compressive stress field within the component, buckling may occur, and an evaluation in accordance with 5.4 may be required." such statement is mentioned again and again in part 5, but how to determine if there is a compressive stress field? look up the principal stress for negative stress in FEA software like ANSYS?

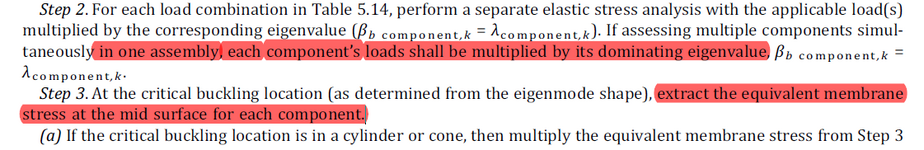

2. step 2 of method A indicates that "each component’s loads shall be multiplied by its dominating eigenvalue", i perform the eigenvalue buckling analysis for the components ( a cylinder with two heads) in assembly , the eigenvalue from ansys is for the assembly. it's not component-specific, how come i get the eigenvalue of each component ? must the eigenvalue buckling analysis be performed for only one component in a single time? if yes, such analysis must be performed for 3 time in my case, and i think the method is quite hard to apply in reality.

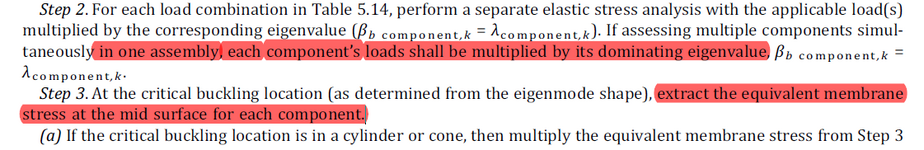

3 . how to "extract the equivalent membrane stress at the mid surface for each component."? is it a linearized stress which shall be extracted by creating a path in ANSYS?

4. i think the rules in para. 5.4 for buckling analysis is so complicated, if possible i would rather choose the the rules in part 4 of ASME VIII-2. could i only use the formulas in part 4 for protection from buckling failure while all other failure modes still be considered per clauses in part 5?

thanks in advance, any reply appreciated.

i am looking at para.5.4 of 2023 asme VIII-2, and have some questions regarding the buckling analysis, please shed me some light:

1. "if the applied loading results in a compressive stress field within the component, buckling may occur, and an evaluation in accordance with 5.4 may be required." such statement is mentioned again and again in part 5, but how to determine if there is a compressive stress field? look up the principal stress for negative stress in FEA software like ANSYS?

2. step 2 of method A indicates that "each component’s loads shall be multiplied by its dominating eigenvalue", i perform the eigenvalue buckling analysis for the components ( a cylinder with two heads) in assembly , the eigenvalue from ansys is for the assembly. it's not component-specific, how come i get the eigenvalue of each component ? must the eigenvalue buckling analysis be performed for only one component in a single time? if yes, such analysis must be performed for 3 time in my case, and i think the method is quite hard to apply in reality.

3 . how to "extract the equivalent membrane stress at the mid surface for each component."? is it a linearized stress which shall be extracted by creating a path in ANSYS?

4. i think the rules in para. 5.4 for buckling analysis is so complicated, if possible i would rather choose the the rules in part 4 of ASME VIII-2. could i only use the formulas in part 4 for protection from buckling failure while all other failure modes still be considered per clauses in part 5?

thanks in advance, any reply appreciated.