Jeter316

Mechanical

- Mar 18, 2010

- 6

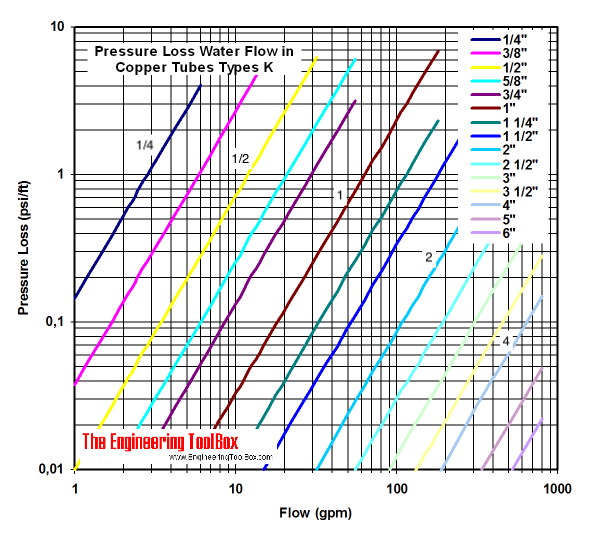

What is the best way to determine water pressure and flow through a line when all I know is the entering pressure? I have a 1" water line that I would like to take about 300ft up a hill and I' have my doubts as to whether or not I have enough pressure. I estimate the pressure on the existing 1in line to be ~45psi. The elevation difference is about 80ft. Thanks.

![[frog] [frog] [frog]](/data/assets/smilies/frog.gif)