OK, sometimes it's better to NOT try and move all the faces. Only select the ones that are really controlling the location of, in this case, the 'bead', and let the software do the hard work.

So for your model, this is the workflow that you need to follow:

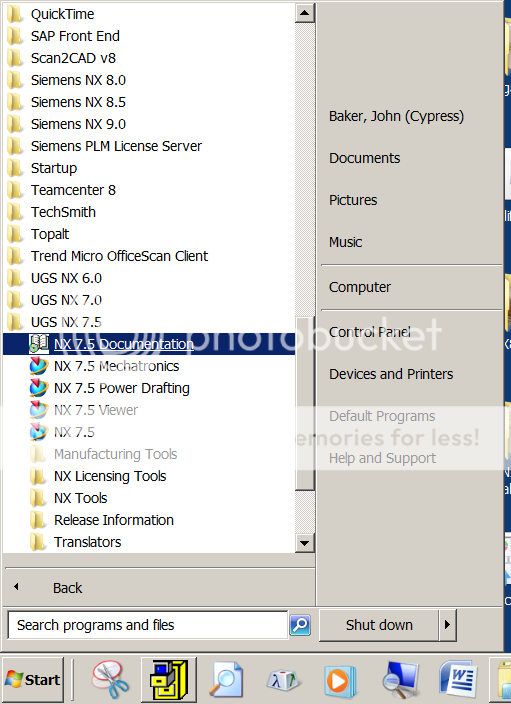

First, open the Part Navigator and select the 'Delete Face' feature, press MB3 and select the 'Make Current Feature' option. This will, for all intents and purposes, suppress everything created after this feature but more importantly it will 'move' you back in time to a 'Time Stamp' BEFORE these features were created.

Second, go into 'Move Face', set the 'Motion' to 'Distance' and with the 'Face Rule' set to 'Single Face' select ONLY the two small, narrow planar faces which makes up the SIDES of the bead. Do NOT select any of the blends. Press MB2 (Middle Mouse Button) to move the dialog focus to the 'Specify Vector' item, then select the cylindrical face of the 'tube' to define the direction 'Vector' and now you can either drag or enter the distance value that you wish to move the 'bead'.

Last, now that you have your 'bead' where you want it, go back to the Part Navigator, select the LAST feature on the list, press MB3 and select the 'Make Current Feature' option and you're done.

in the furture is need to you can now adjust the location of the 'bead' by simply editing the new 'Move Face' feature.

OK, the lessen learned here is that with Synchronous Modeling, it's often best to select ONLY those faces which must be moved and let the software do the hard work of moving the adjacent faces which will NEED to update in order to move the faces that YOU selected.

Anyway, give it shot and let us know how it worked.

John R. Baker, P.E.

Product 'Evangelist'

Product Engineering Software

Siemens PLM Software Inc.

Industry Sector

Cypress, CA

Siemens PLM:

UG/NX Museum:

To an Engineer, the glass is twice as big as it needs to be.