R

rbarata

Guest

Hello, my friends

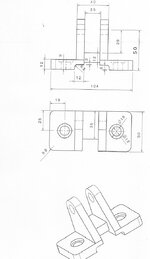

I'd like your oppinion about the strategy I used in my next exercise. I didn't used the dimensions in the drw, this is just a try.

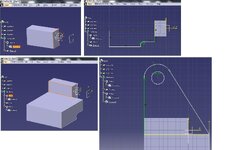

First I created half of the central pad based on a simple sketch (a rectangle) and then an offset plane (pic 1).

Using this iffset plane, I created the second sketch (I used a projected edge from pad 1 to keep it together) (pic 1).

Then, used the pad face as a support for sketch 3 (pics 1). Again, used a projected edge to keep it all together.

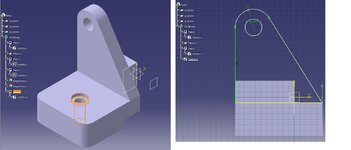

Then created a counterbored hole and rounded the pad edges with two edge fillets (pic 5).

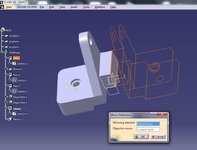

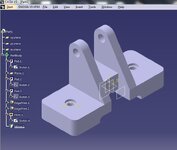

Finally, I mirrored the "half-part" (pic 6 & 7).

This seemed to me a simple way to construct this part but if you have other sugestions, please send them.

Thank you

I'd like your oppinion about the strategy I used in my next exercise. I didn't used the dimensions in the drw, this is just a try.

First I created half of the central pad based on a simple sketch (a rectangle) and then an offset plane (pic 1).

Using this iffset plane, I created the second sketch (I used a projected edge from pad 1 to keep it together) (pic 1).

Then, used the pad face as a support for sketch 3 (pics 1). Again, used a projected edge to keep it all together.

Then created a counterbored hole and rounded the pad edges with two edge fillets (pic 5).

Finally, I mirrored the "half-part" (pic 6 & 7).

This seemed to me a simple way to construct this part but if you have other sugestions, please send them.

Thank you