Steve Hanson

Structural

- Jul 19, 2025

- 5

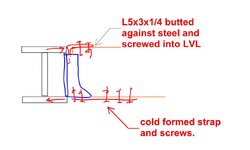

Lvl beam was cut roughly 1-1/4 inches to short. The LVL beam runs perpendicular to a steel beam and is attached to the steel beam via a ledger board. The LVL beam run about 8 feet long and connected to the sub floor with the appropriate engineered nails. One side of the LVL is attached to floor joists via hangers. The other side of the lvl has floor joists with blocking. One side of the lvl is connected by hanger to wood beam running perpendicular to the lvl (this connection is fine and is flush to the other wood beam) I have attached a photo which shows the lvl in hanger with the 1-1/4 inch gap.

Questions.

1. Can I leave this as is and be ok?

2. What other options for repair exist without removing and replacing the lvl? I don't want to remove flooring and drywall to make the repair.

3. As an option, could I remove the subfloor from above and run 2d nails into end of lvl and ledger board and fill void with an engineered epoxy structural adhesive? This would fill void and not allow beam to slide towards steel beam and help to keep connected. Picture attached below.

Questions.

1. Can I leave this as is and be ok?

2. What other options for repair exist without removing and replacing the lvl? I don't want to remove flooring and drywall to make the repair.

3. As an option, could I remove the subfloor from above and run 2d nails into end of lvl and ledger board and fill void with an engineered epoxy structural adhesive? This would fill void and not allow beam to slide towards steel beam and help to keep connected. Picture attached below.