1st off, not like anything I've seen/I don't recognize the formatting. BUT It sure feels familiar.

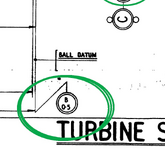

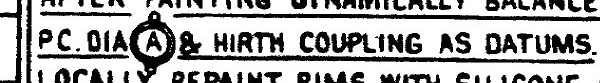

Looking at -A- I'm guessing a Datum simulator/gage tooling, is installed into the associated bolt circle to establish a central axis from which A1 dimensions are pulled. Basically saying hey this dimension is associated with gage A, and A1 is probably a bar offset a known distance from the central axis for sweeping a test indicator on OD surfaces. All the A1 dims appear to be the most unsupported portion of the thinwall OD, thus check in this area per the note "for this length" 2.850 for the first A1 on the left.

If I had to guess I bet the part sits flat on -A-, in a vertical orientation. B is probably mounts on the end of A for checking length. C, is probably a "complication"... an "add on" to the -A- simulator. to grab the diameter of the Hirth coupling. D, is probably a dial indicator to position the minimum of that groove to establish part clocking because that clocks the 1 offset hole in the 12 hole BC. E, is a tool that gets concentricity between the inside and outside... I bet its a "C" frame that slides onto or clamps onto the A axis.

I bet I know exactly what that tool looks like... at least I know what It looks like in my head.

I've had to build tools like this for gaging DCMA parts designed from way back before a CMM, and no alternate means were approved. Building a really nice datum simulator to sweep test indicators from was the only way. We finally got smart and just convinced them the CMM could pull it off.

Absolute nightmare part.