Scotty Boy

Structural

- Mar 11, 2025

- 21

Hi,

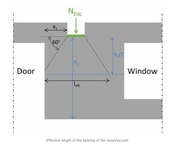

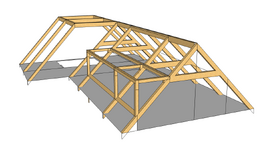

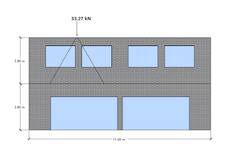

I am attempting the design the following masonry wall:

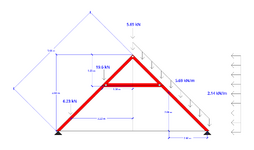

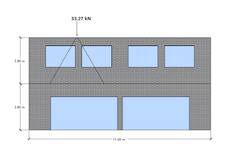

The wall is under two point loads. One is vertical as you can see in the diagram that has a magnitude of 33.27 kN. There is also another point load and it is horizontal and going into the page at the same location as the vertical point load. This has a magnitude of 30.74 kN. The forces are the result of a roof truss that has a pinned support. Hence, there is a vertical and horizontal reaction on the wall.

I am okay with designing the wall for the vertical load, but I don't know much about masonry under horizontal loads, especially point loads. So, I am wondering if someone could give me some direction on how I design the wall due to the horizontal point load at the top?

Many thanks!

I am attempting the design the following masonry wall:

The wall is under two point loads. One is vertical as you can see in the diagram that has a magnitude of 33.27 kN. There is also another point load and it is horizontal and going into the page at the same location as the vertical point load. This has a magnitude of 30.74 kN. The forces are the result of a roof truss that has a pinned support. Hence, there is a vertical and horizontal reaction on the wall.

I am okay with designing the wall for the vertical load, but I don't know much about masonry under horizontal loads, especially point loads. So, I am wondering if someone could give me some direction on how I design the wall due to the horizontal point load at the top?

Many thanks!