I have been trying to test run an induction vertical motor with spherical roller bearing on the NDE. This bearing is inside a cartridge under which there are springs. The entire assembly goes inside the bearing housing. The DE has a deep groove ball bearing (guide bearing). The axial play was set to 0.008- 0.010 ".

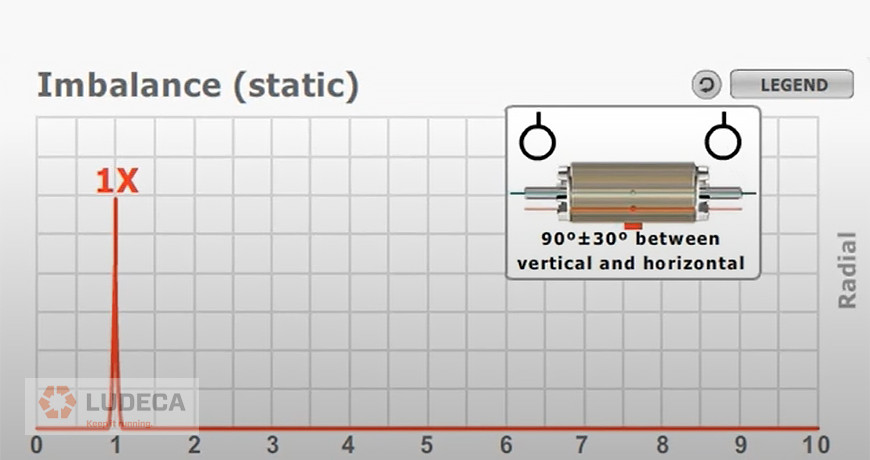

During the test run (unloaded) the vibration amplitude seems to be cycling between 0.13 ips to 0.44" ips in a span of 15 mins and all at 1xRPM (1800). The phase angle of unbalance does not change by much (270 -284 deg)

What could be the cause for this? What is the testing procedure OEM follows to test run this motor unloaded?

During the test run (unloaded) the vibration amplitude seems to be cycling between 0.13 ips to 0.44" ips in a span of 15 mins and all at 1xRPM (1800). The phase angle of unbalance does not change by much (270 -284 deg)

What could be the cause for this? What is the testing procedure OEM follows to test run this motor unloaded?