Stressman76

Mechanical

- Sep 9, 2015

- 7

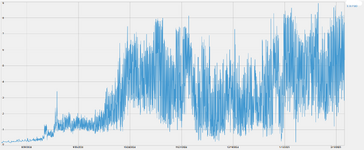

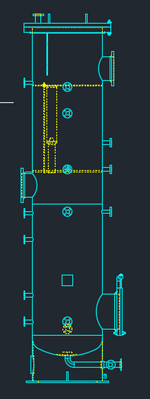

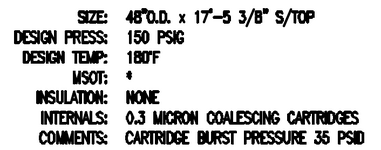

Hi all. At the site I am working at we have a fuel gas coalescer which keeps having filter media burst before the Cartridge Burst Pressure DP is reached. Any ideas or insights on to why this may be happening? The burst pressure dp is significantly higher than what we reach.