In most cases, it's standard to not go directly from 30 kV to 0.4 kV. The more common practice is to step down the voltage in stages, typically from 30 kV to 6 kV, then from 6 kV to 0.4 kV.

Any advantages (economical, technical) of it?

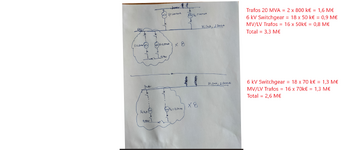

Attached example.

Any advantages (economical, technical) of it?

Attached example.

![IMG20250611134157[1].jpg](/data/attachments/10/10669-9cc1785e511117fb139479c150943443.jpg?hash=nMF4XlERF_)