Hey all,

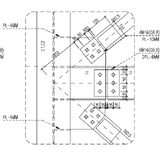

I'm looking to get some input on what the common practice is for giving moment to an HSS column that is loaded by a shear tab connection. Is it standard to offset the load by half the column width + ~1 1/2" to the first row of bolts? For cases where connections are delegated and you don't know the # of bolt columns, should you take a higher offset to account for the true centroid of bolts?

I know RISA Connection allows you to ignore moments in the connection if the offset isn't that large, but does this mean that the column doesn't experience any moment as well?

With HSS you rarely have a concentric loading case unless you're running a gerber beam system above or explicitly detail a bearing connection, but I know that columns are just take with the typical compression equation and not really any moment.

In my case, we are doing a 4 storey building so I've been including the connection offset and pattern loading the live loads on either side to get a moment envelope, but it's making my column sizes way larger than we originally anticipated.

I'm looking to get some input on what the common practice is for giving moment to an HSS column that is loaded by a shear tab connection. Is it standard to offset the load by half the column width + ~1 1/2" to the first row of bolts? For cases where connections are delegated and you don't know the # of bolt columns, should you take a higher offset to account for the true centroid of bolts?

I know RISA Connection allows you to ignore moments in the connection if the offset isn't that large, but does this mean that the column doesn't experience any moment as well?

With HSS you rarely have a concentric loading case unless you're running a gerber beam system above or explicitly detail a bearing connection, but I know that columns are just take with the typical compression equation and not really any moment.

In my case, we are doing a 4 storey building so I've been including the connection offset and pattern loading the live loads on either side to get a moment envelope, but it's making my column sizes way larger than we originally anticipated.