DoubleStud

Structural

- Jul 6, 2022

- 507

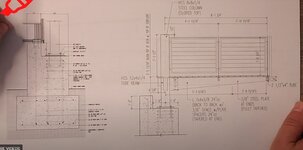

I found this video on youtube. What do you think of this deck? The guy went to the end of the deck and jumped a little bit, you can clearly see the deck moves up and down. At minute 3:55 he shows the structural detail.