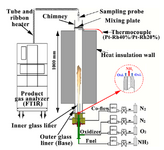

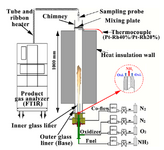

Think there is an error in that writeup - the inner glass liner of 72mm dia is not 1000mm height. It is the outer 90mm glass liner, which forms the base of the cylindrical insulation, which is 1000mm. Height of the 72mm inner liner is not stated, but is shown to be much less than 1000mm looking at Fig 1.

This is a complex topic about the NOx emissions characteristics of the flue gas from NH3 combustion, and though I have read some literature on this topic, must say this is a black art to me, and raises more questions than it answers. There are numerous instances of negative feedback from the operation of so called Lo NOx gas turbines even with simpler natural gas as fuel source. Personally, I have opposed the deployment of Low NOx GT in the interest of saving CAPEX, disappointing feedback, and the narrow range of fuel gas compositions and fuel gas flows that these machines require which causes all sorts of problems and challenges from an engineering design / Operations perspective.