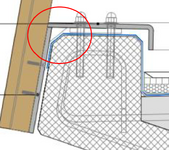

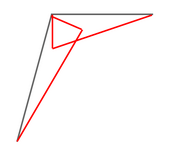

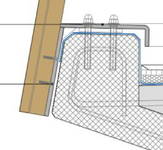

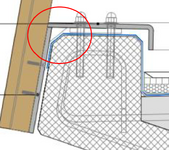

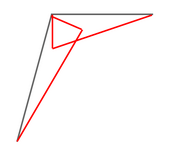

I'm working on an steel element for assembling a railing on footbridge. It's supposed to be a steel cold bent or welded module attached to concrete parapet by anchors. For the moment a corner at the post is presumed to be welded and locally stiffend by small rib. However I thought to cold bend it instead of welding. This node will be subjected to bending moment (closing or opening like on the sketch below), which means, that the direction of stresses will be the same as during cold bent process and section capacity may be limited. My question is how a yield strength is affected by cold bending process in such a case. The second issue is a minimum bending radius, which can be used. How can I determine it?

Generally I checked Eurocode 1993-1-3 but it covers rather profiles, where cross section is cold bent.

Generally I checked Eurocode 1993-1-3 but it covers rather profiles, where cross section is cold bent.