Hello,

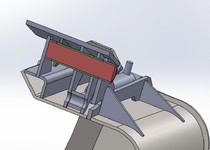

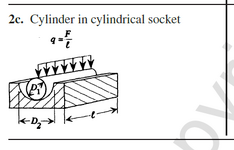

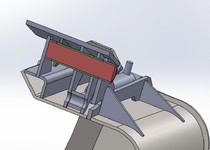

I am designing a hinge system where a round tube (green) will rotate around a solid rod (red). The tube length is about 8"(200mm). My question is, what hole/shaft clearance basis would be best to use?

The tube will be tapped/threaded for a grease zerk. The max rotation is 90 degrees, and the speed will be 5 RPM max. The pin needs to be able to be assembled by hand. I attached a section view below. I know the wall of the green tube looks thin... I'm working on that as well.

I am designing a hinge system where a round tube (green) will rotate around a solid rod (red). The tube length is about 8"(200mm). My question is, what hole/shaft clearance basis would be best to use?

The tube will be tapped/threaded for a grease zerk. The max rotation is 90 degrees, and the speed will be 5 RPM max. The pin needs to be able to be assembled by hand. I attached a section view below. I know the wall of the green tube looks thin... I'm working on that as well.