Redcobra2401

Automotive

- Mar 25, 2024

- 13

let me start off by saying that, I am no engineer. never went to college just a trucker with a lot of free time in the sleeper and an obsession with anything mechanical.

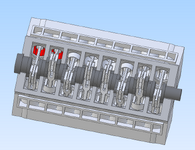

I am currently designing a 905cui 90-degree v16 that is a flat head/L-head, my current crank design won't accommodate a standard firing order, like that in the Cadillac v16 of back when, I'm wondering if it can be balanced. Would a simple harmonic balancer suffice or if some counterweights on the crank would help with the vibrations? the rpm limit I'm shooting for is around 3500 rpm and projected compression ratio is between 6.5:1 and 7.5:1.

there are 3 possible firing orders I have come up with, this is really difficult to attempt to wrap my head around and I've spent the good part of 5 hours getting a migraine from just getting this far with it. I'm trying to have to keep from scraping the whole crank shaft and starting over, the whole reason for designing it the way i did was to make it easy to machine not requiring counterweights for the primary balance.

1,2,7,8,13,14,5,6,15,16,9,10,3,4,11,12 -

1,2,9,10,3,4,11,12,15,16,7,8,13,14,5,6 -

1,9,3,11,15,7,13,5,2,10,4,12,16,8,14,6 -

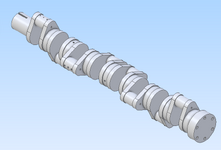

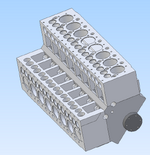

attached are snap shots of the crank and the current assembly. any and all help is welcome especially a solution.

I am currently designing a 905cui 90-degree v16 that is a flat head/L-head, my current crank design won't accommodate a standard firing order, like that in the Cadillac v16 of back when, I'm wondering if it can be balanced. Would a simple harmonic balancer suffice or if some counterweights on the crank would help with the vibrations? the rpm limit I'm shooting for is around 3500 rpm and projected compression ratio is between 6.5:1 and 7.5:1.

there are 3 possible firing orders I have come up with, this is really difficult to attempt to wrap my head around and I've spent the good part of 5 hours getting a migraine from just getting this far with it. I'm trying to have to keep from scraping the whole crank shaft and starting over, the whole reason for designing it the way i did was to make it easy to machine not requiring counterweights for the primary balance.

1,2,7,8,13,14,5,6,15,16,9,10,3,4,11,12 -

1,2,9,10,3,4,11,12,15,16,7,8,13,14,5,6 -

1,9,3,11,15,7,13,5,2,10,4,12,16,8,14,6 -

attached are snap shots of the crank and the current assembly. any and all help is welcome especially a solution.