asalisbury

Mechanical

Hi All,

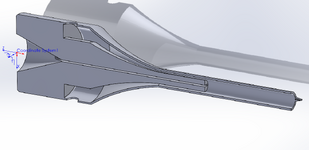

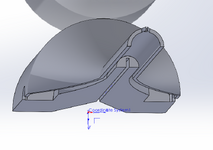

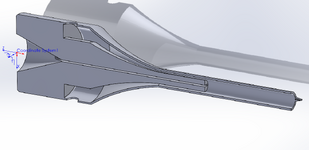

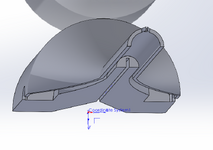

I am attempting to make an air jet weaving nozzle, having never done so before, and need some help with the air jet design for weaving fibers with a rectangular cross section. I have a few pictures below for what I am currently working with. My trials so far have not worked mostly due to high friction on the fiber in its chamber - I am printing another nozzle with a larger chamber to accommodate this.

The fiber chamber has a rectangular cross section, and I have four 1/4" air inlets that I connect to shop air at ~40psi. The air accelerates through a throat and creates a vacuum around the fiber exit causing it to move forward. I need to keep the fiber in a rectangular cross section to maintain its stiffness for weaving.

Any notes or help on this would be appreciated!

I am attempting to make an air jet weaving nozzle, having never done so before, and need some help with the air jet design for weaving fibers with a rectangular cross section. I have a few pictures below for what I am currently working with. My trials so far have not worked mostly due to high friction on the fiber in its chamber - I am printing another nozzle with a larger chamber to accommodate this.

The fiber chamber has a rectangular cross section, and I have four 1/4" air inlets that I connect to shop air at ~40psi. The air accelerates through a throat and creates a vacuum around the fiber exit causing it to move forward. I need to keep the fiber in a rectangular cross section to maintain its stiffness for weaving.

Any notes or help on this would be appreciated!